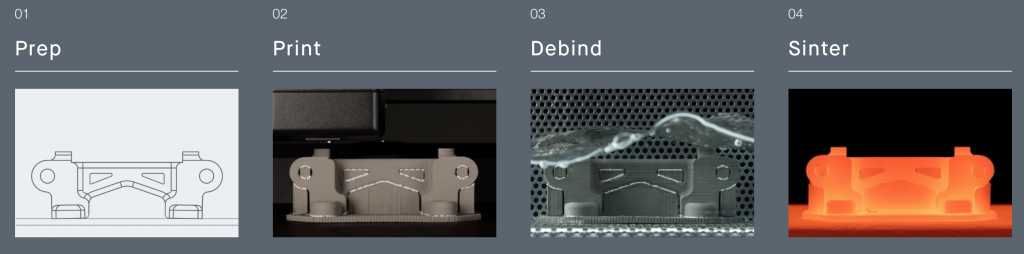

Vista rápida de la Impresora

Vista rápida: Studio System+ para creación rápida de prototipos (estudio de caso)

Call Today!

Micro Plus Alta Resolución

Precio Directo de Fábrica a Puerto Rico.

USD 24,858*

Incluye:

- Impresora 3D

- Horno de Curado

- 2 Kgs de Resina

- Instalación

- Capacitación

- Mantenimiento por un año

*No incluye: Envío, Impuestos, Viaje del Instructor / Instalador

Excelente máquina de arranque para joyeros. La familia Micro Plus de impresoras 3D es ideal para una amplia variedad de aplicaciones profesionales de impresión 3D que requieren precisión, confiabilidad y un acabado de superficie uniforme que minimiza el procesamiento posterior.

Perfactory 4K Series

FACTORY DIRECT TO PUERTO RICO

ALL INCLUSIVE

USD 134,197

The Perfactory 4K Series brings new, larger size capabilities to EnvisionTEC’s arsenal of 3D printers recognized for their smooth finished prints. Our new 3D printer with LED system comes in 4 build envelopes and XY resolutions. This is printer is capable of producing parts for final end-use, investment casting patterns, medical devices, prototypes and more in at least 22 materials. Switching materials has never been easier and requires no material bleeding.

Includes: • Machine • Starter Resin • Curing Oven • Training • Maintenance

Call to Start Printing Parts Today!

787.360.7920

This is an advanced course in additive manufacturing for the industrial sector. The course will focus on the following topics:

- metal additive manufacturing;

- plastic additive manufacturing;

- designing parts for industry and software;

- the 6 main contributions to geometrical accuracy;

- lean manufacturing and additive manufacturing;

- case studies of industrial use of metal & plastic printers;

- Site visit to an industrial printer.

This course will take place during the months of February and March of 2018.

We will meet for 1.5hrs every Saturday for seven weeks. Upon completion of the course there will be a 3 hour final exam.

Only those that score a grade of B or better on all the subtopics will receive certification of course understanding. Everyone else will receive proof of attendance in the course. NO EXCEPTIONS.

This course is ideal for someone that wants to have advanced knowledge of additive manufacturing as it applies to the industrial setting. The ideal student should be self motivated towards study and participate in class discussions.

This course will cost $300 per person.

Sign up here for more details as they become available.

EnvisionTEC introduces

THE FIRST INDUSTRIAL SCALE 3D PRINTER

for the

PRODUCTION of WOVEN FIBER COMPOSITE PARTS

EnvisionTEC, a leading global manufacturer of professional grade 3D printing solutions, announced today the launch of the SLCOM™ 1 industrial composite 3D printer. EnvisionTEC, who has a history of driving innovation in 3D printing developed and commercialized the first DLP 3D printer to market in 2002. Following years of consistent innovation, EnvisionTEC has yet another first to market 3D printer in the SLCOM 1, employing a new patent pending process known as Selective Lamination Composite Object Manufacturing.

“We are proud to introduce the first disruptive industrial-scale, composites 3D printer. This represents a paradigm shift for manufacturing, especially where demanding mechanical and environmental properties can only be delivered from woven composites”, said Al Siblani, CEO of EnvisionTEC.

SLCOM technology allows for the building of composite parts using layer-by-layer laminated thermoplastic composite fabric sheets from a roll. As the first 3D printer employing this technology, the SLCOM 1 will be capable of building objects up to 24” x 30” with a 24” height.

The SLCOM 1 can process a wide range of custom made thermoplastic reinforced unidirectional or multidirectional woven fibers tailored to the customer performance needs. Some of the composite matrix materials the SLCOM 1 can process include woven glass fiber, woven carbon fiber, or other woven aramid fibers reinforced with a choice of Nylon 6, Nylon 11, Nylon 12, Peek, Pekk, Polycarbonate, and many others. This allows for customization in delivering high quality 3D printed parts suitable for use in aerospace, automotive, consumer products, sporting goods, and potential applications in the medical space. The composites can be tailored for exceptional toughness, environmental resistance, vibration dampening, low flammability characteristics, high wear resistance and high strength to weight ratio.

“It is exciting to consider the extensive range of new applications that the SLCOM 3D printing technology will open up. EnvisionTEC has long been a pioneer in 3D printing innovations and we believe that this entry into the composites space will propel industrial 3D printing to a host of new applications”, said Siblani.

This printer will be available in Puerto Rico only through Rich Port 3D Solutions.

Call Today

787.360.7920

The Micro Plus family of 3D printers provides the ideal desktop companion for a wide variety of 3D printing applications. Available in two configurations, the Micro Plus series is a professional grade 3D printing solution utilizing an industrial UV LED light source and an integrated, embedded PC with Wi-Fi. The touchscreen adds convenience to the user interface, allowing for the necessary files for print to quickly and easily be transferred from any network computer directly to the Micro Plus via Wi-Fi. The Micro Plus 3D printers can produce functional parts with exceptional surface quality without sacrificing speed. The materials available for the Micro Plus line cover a wide range of applications, including jewelry, toy, medical, industrial design and engineering, and more.

This objective of this magazine is to demonstrate to the industrial community the possibilities in 3D printing for Puerto Rico specifically through EnvisionTEC 3D printers. Judge for yourself if EnvisionTEC printers are right for you.

Dr Jenny Carrero the magazine editor is the principal consultant for Rich Port 3D Solutions: Your Puerto Rico 3D Printing Resource. She is an expert in the application of 3D printing for dental, medical and industrial applications.

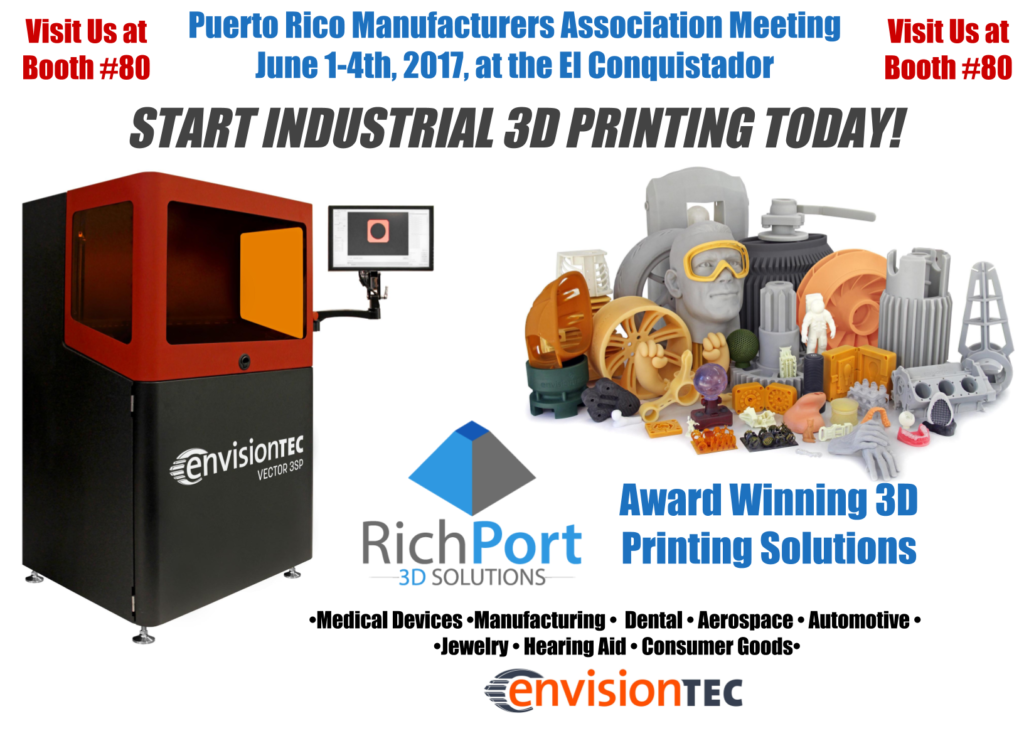

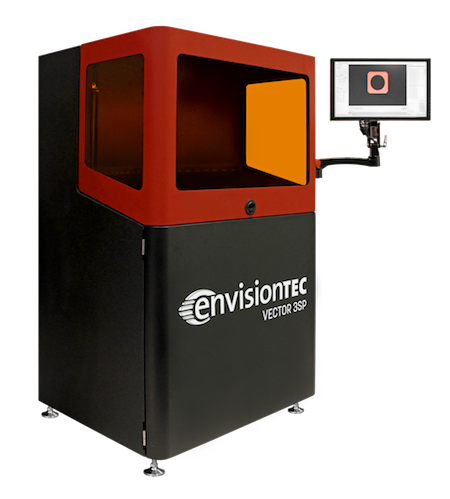

Vector 3SP®

EnvisionTEC’s Vector 3SP® 3D printer allows for production of large 3D parts at fast build speeds without sacrificing the surface quality and part accuracy that EnvisionTEC is known for. The Vector 3SP uses EnvisionTEC’s 3SP (Scan, Spin, and Selectively Photocure) technology to quickly 3D print highly accurate parts from STL files regardless of geometric complexity. The Vector 3SP® is delivered and installed with all the relevant software to enable automatic generation of supports and perfect model production. The surface quality of the printed models show no signs of stairstepping on the inner and outer surfaces. The Vector 3SP includes a build envelope that is 29% larger than the ULTRA 3SP with increased speed capabilities making it an attractive solution for a wide range of manufacturing applications.

Benefits

- A single material is used for both build and easily removable, partially cured perforated supports

- Very few moving parts make the system user-serviceable

- Low part cost due to minimal material waste

- Produce everything from concept models to functional parts

Materials Available

-

ABS 3SP Flex (Black, Gray, White): Models similar to ABS plastic with flexibility characteristics

-

ABS 3SP Tough: Rigid, stable models similar to those made with ABS plastic

-

ABS TRU 3SP: Rigid, stable models similar to those made with ABS plastic

-

ABS 3SP Superflex: Models similar to ABS plastic with flexibility characteristics

-

E-Tool 3SP: 3D printed molds for thermoplastic injection molding quickly and efficiently

-

E-Denstone 3SP Peach: General purpose, high temperature molding, concept models

-

E-Glass 3SP: Strong, clear material with flexible capabilities

Machine Specifications*

-

Build Envelope: 11.8″ x 7.9″ x 7.9″ (300 x 200 x 200 mm)

-

Resolution in X and Y: 0.004″ (100µm)

-

Dynamic Voxel Resolution in Z**: 0.002″ – 0.004″ (50 – 100 µm) – user adjustable

*Specifications subject to change without notice.**Material dependent

System Properties

-

Footprint (L x W x H): 36″ x 36″ x 60″ (91 x 91 x 152 cm)

-

Weight: 423 lbs (192 kg)

-

Electrical Requirements:

220 Volt, Single Phase, 5 Amps

110 Volt, Single Phase, 10 Amps -

Data Handling – STL

-

Warranty – 1 year included on machine

System Data Handling

-

Can connect directly to a PC workstation or be integrated into a network for pre-processing of the job files and for remote monitoring

-

The system has a stand-alone PC with a 15” touchscreen monitor

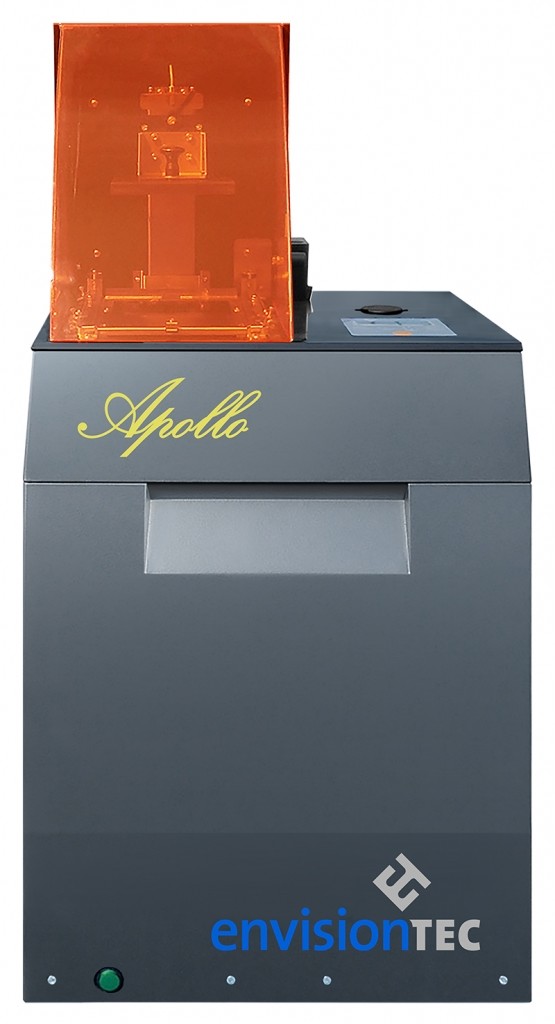

Perfactory® Apollo

The Apollo is the new desktop 3D detailed small piece printer with an enlarged build envelope for small pieces with an unbeatable price to performance ratio. The Apollo is the perfect choice for the small to medium sized company looking to fulfill their 3D printing production requirements. With the ability to run unattended, 24 hour production is achievable. The Apollo can run a variety of 3D printing materials for direct casting, hot rubber, and silicone molding. There are no limits to geometric complexity as long as the item has been designed in a 3D CAD program and may be exported as an STL file. The 3D printer machines are delivered and installed with all the relevant software to enable automatic support generation and perfect model production. Resolution and surface finish remains constant over the entire build area due to patented technology based on voxelisation.

Benefits:

- Easy handling through pre-adjusted material modules

- Build speed is constant through the build up to 0.12″ (3mm) to 0.28″ (7mm) per hour at 0.0014″ (35 μm) Z-voxel thickness (material dependent)

- Very few moving parts and minimal consumable components guarantee a strong and reliable system

- Utilizing a built in ethernet interface, can connect directly to a PC workstation or be integrated into a network

- Changeover between 3D printer materials is done quickly and easily

Materials Available

-

R5, R5 Gray, R11 – Cold silicone molding with high resolution

-

PIC 100, PIC 100G – Direct casting

-

WIC 100G – Direct Casting

-

EC500 – Direct Casting

-

RCP30, RC31, RC70, RC90, Photosilver – HTV Molding

-

HTM140 – HTV Molding with minimal post finishing

-

EPIC – Direct Casting

Machine Specifications*

-

Build Envelope: 3.94″ x 2.95″ x 3.94″ (100 x 75 x 100 mm)

-

Projector Resolution: 1400 x 1050 pixels

-

Native Pixel Size: 0.0028″ (71 µm)

-

Dynamic Voxel Resolution in Z**: 0.001″ 0.0059” (25 µm x 150 µm)

*Specifications subject to change without notice.

**Material dependent

System Properties

-

Footprint (L x W x H): 21.65″ x 17.72″ x 35.03″ (55 x 45 x 89 cm)

-

Weight: 77.16 lb (35 kg)

-

Electrical Requirements: 100-120V, 2 Amps or 220-240V, 1 Amp

-

Data Handling – STL

-

Warranty – 1 year

System Data Handling

-

Utilizing a built in Ethernet interface, the Apollo can easily connect directly to a PC workstation or be integrated into a network. The Apollo has an embedded PC, allowing the system to work independently from the pre-processing workstation. The machine can be remotely monitored from any computer on the network using the communication software from the Apollo Software Suite. Any STL data format can be easily imported using the Apollo Software Suite.

EnvisionTEC 3D Industrial Printers Printers Spec Sheet Available through Rich Port 3D Solutions

The ULTRA® 3SP® Ortho model 3D printer uses groundbreaking 3SP® (Scan, Spin, and Selectively Photocure) 3D printing technology to quickly 3D print highly accurate dental models for use in producing high quality orthodontic appliances. The surface quality of the printed models allows for a clear aligner with no signs of stair-stepping, which is visible when using competing technologies. The models produced are very stable over time and have negligible water absorption. The model material is a high temperature material which allows for the production of a clear aligner without any distortion in the model during vacuum forming under heat.

Create up to 40 3D printed Orthodontic Models on 1 build!

Benefits:

- Simple user interface with built-in touch screen

- Very few moving parts and minimal consumable components guarantee a strong and reliable system

- Office friendly plug-and-play operation with a built in touch screen

- Low part cost due to minimal material waste

- Remote notification when job is complete

- Lowest operational costs in its class

Materials Available

-

ABS 3SP® White: General purpose, high temperature molding, concept models

-

E-Denstone 3SP® Peach: General purpose, high temperature molding, concept models

-

Ortho Tough 3SP®: Orthodontic models for thermoforming method

-

E-Appliance 3SP® – Orthodontic models for salt and pepper technique

Consumables

-

PSA: Pre-Stretched Consumable Assembly available with or without core return

Machine Specifications*

-

Build Envelope: 10.5″ x 6.9″ x 3″ (266 x 175 x 76 mm)

-

Resolution in X and Y: 0.004″ (100µm)

-

Dynamic Voxel Resolution in Z**: 0.001″ – 0.004″ (25 – 100 µm) – user adjustable

*Specifications subject to change without notice.

**Material dependent

System Properties

-

Footprint (L x W x H): 29” x 30” x 46” (74 x 76 x 117 cm)

-

Optional Stand (L x W x H): 29″ x 30″ x 25″ (74 x 76 x 64 cm)

-

Weight: 198 lbs (90 kg)

-

Electrical Requirements: 100-127 VAC, 50/60 Hz, single phase, 8A

200-240 VAC, 50 Hz, single phase, 4A -

Data Handling: STL

-

Warranty: 1 year included on machine

System Data Handling

-

Utilizing a built in Ethernet interface, the ULTRA® 3SP® Ortho can easily connect directly to a PC workstation or be integrated into a network. The ULTRA® 3SP® Ortho has an embedded PC, allowing the system to work independently from the pre-processing workstation. The machine can be remotely monitored from any computer on the network using the communication software from the ULTRA® Software Suite. Any STL data format can be easily imported using the ULTRA® Software Suite.

EnvisionTEC 3D Industrial Printers Printers Spec Sheet Available through Rich Port 3D Solutions

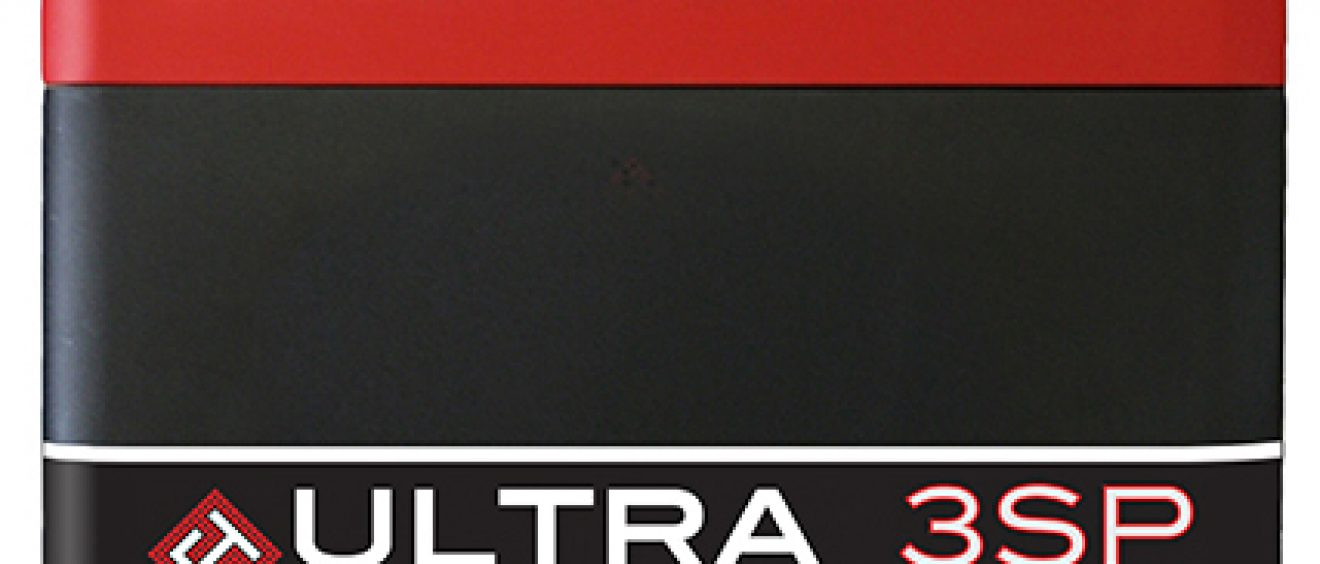

ULTRA® 3SP® and 3SP® HD

EnvisionTEC’s ULTRA® 3SP® 3D Printer Series uses ground-breaking 3SP® (Scan, Spin and Selectively Photocure) technology to quickly 3D print highly accurate parts from STL files regardless of the geometric complexity. The ULTRA® 3SP® and 3SP® High Definition 3D Printers are each delivered and installed with all the relevant software to enable automatic generation of supports and perfect model production. The surface quality of the printed models show no signs of stair-stepping on the inner and outer surfaces. The reliability of the imaging light source and the high speed productivity makes it the most competitive 3D printer on the market today.

Benefits:

- A single material is used for both build and support

- Easily removable partially cured perforated supports

- Very few moving parts make the system user serviceable

- Office friendly plug-and-play operation with a built-in touch screen

- Low part cost due to minimal material waste

- Produce everything from concept models to functional parts

- Layerless technology with no stair-stepping on inner and outer surfaces

- Quiet operation

Materials Available

-

ABS 3SP® Flex (Black, Gray, White): Models similar to ABS plastic with flexibility characteristics

-

ABS 3SP® White: Models similar to ABS plastic

-

ABS 3SP® Tough: Rigid, stable models similar to those made with ABS plastic

-

ABS 3SP® Superflex: Models similar to ABS plastic with flexibility characteristics

-

E-Denstone 3SP® Peach: General purpose, high temperature molding, concept models

-

E-Glass 3SP®: Strong, clear material with flexible capabilities

Consumables

-

PSA: Pre-Stretched Consumable Assembly available with or without core return

Machine Specifications*

-

Build envelope XYZ: 10.5” x 6.9” x 7.6” (266 x 175 x 193 mm)

System Properties

-

Footprint (L x W x H): 29” x 30” x 46” (74 x 76 x 117 cm)

-

Optional Stand (L x W x H): 29″ x 30″ x 25″ (74 x 76 x 64 cm)

-

Weight: 198 lbs (90 kg)

-

Electrical Requirements: 100-127 VAC, 50/60 Hz, single phase, 8A

200-240 VAC, 50 Hz, single phase, 4A -

Data Handling – STL

-

Warranty – 1 year included on machine

System Data Handling

-

Utilizing a built in Ethernet interface, the ULTRA® 3SP® can easily connect directly to a PC workstation or be integrated into a network. The ULTRA® 3SP® 3D Printer has an embedded PC, allowing the system to work independently from the pre-processing workstation. The machine can be remotely monitored from any computer on the network using the communication software from the ULTRA® Software Suite. Any STL data format can be easily imported using the ULTRA® Software Suite.

EnvisionTEC 3D Industrial Printers Printers Spec Sheet Available through Rich Port 3D Solutions

Xtreme® 3SP® Ortho

Xtreme® 3SP® Ortho large format 3D printers allow for production of orthodontic models, built at fast build speeds without sacrificing surface quality and part accuracy. The Xtreme® 3SP® Ortho uses EnvisionTEC’s 3SP® (Scan, Spin, and Selectively Photocure) technology to quickly 3D print highly accurate orthodontic models in large batch quantities. The Xtreme® 3SP® Ortho is delivered and installed with all the relevant software to enable perfect model production from a wide range of orthodontic design software. The surface quality of the printed models show no signs of stairstepping on the inner and outer surfaces. The reliability of the light source and the high speed productivity of the Xtreme® 3SP® Ortho makes it one of the most competitive 3D

printers on the market today.

Benefits:

- A single material is used for both build and easily removable, partially cured perforated supports

- Very few moving parts make the system user-serviceable

- Low part cost due to minimal material waste

- Produce everything from concept models to functional parts

- Can connect directly to a PC workstation or be integrated into a network for pre-processing of the job files and for remote monitoring

- The system has a stand-alone PC, which allows it to work independently from the preprocessing workstation

Materials Available

-

E-Denstone 3SP®: High quality orthodontic models

-

E-Appliance 3SP®: Models for orthodontic appliances

-

E-Denstone Tough 3SP®: High quality orthodontic models

-

Ortho Tough 3SP®: High quality orthodontic models

Machine Specifications*

-

Build Envelope: 10″ x 14.25″ x 4″ (254 x 362 x 102 mm)

-

Resolution in X and Y: 0.004″ (100µm)

-

Dynamic Voxel Resolution in Z**: 0.002″ – 0.004″ (50 – 100 µm)

*Specifications subject to change without notice.

** User adjustable – material dependent

System Properties

-

Footprint (L x W x H): 65” x 65” x 65” (165 x 165 x 165 cm)

-

Weight: 890 lbs (404 kg)

-

Electrical Requirements: 220 Volt, single phase, 15A

-

Data Handling – STL

-

Warranty – 1 year included on machine

System Data Handling

-

Can connect directly to a PC workstation or be integrated into a network for pre-processing of the job files and for remote monitoring

-

The system has a stand-alone PC, which allows it to work independently from the pre-processing workstation

EnvisionTEC 3D Industrial Printers Printers Spec Sheet Available through Rich Port 3D Solutions

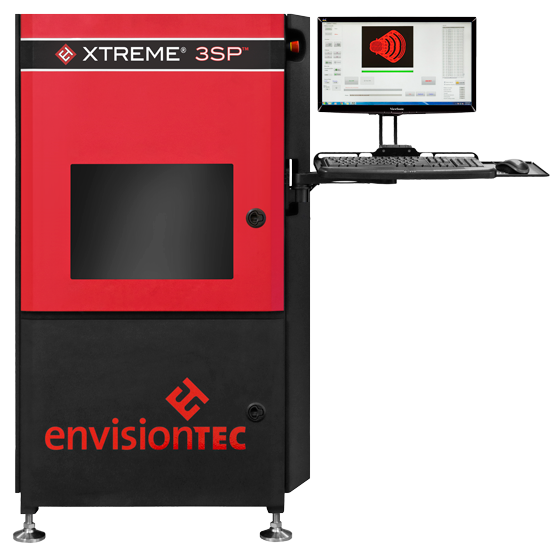

Xtreme® 3SP®

EnvisionTEC’s Xtreme® 3SP® large format 3D printer allows for production of exceptionally large 3D parts, built at fast build speeds without sacrificing surface quality and part accuracy. Xtreme® 3SP® 3D Printer uses EnvisionTEC’s 3SP® (Scan, Spin, and Selectively Photocure) technology to quickly 3D print highly accurate parts from STL files regardless of geometric complexity. The Xtreme® 3SP® 3D Printer is delivered and installed with all the relevant software to enable automatic generation of supports and perfect model production. The surface quality of the printed models show no signs of stairstepping on the inner and outer surfaces. The reliability of the light source and the high speed productivity of these large format 3D printers make them some of the most competitive 3D printers on the market today.

Benefits:

- A single material is used for both build and easily removable, partially cured perforated supports

- Very few moving parts make the system user-serviceable

- Office friendly plug-and-play operation with a built-in touch screen and quiet operation

- Low part cost due to minimal material waste

- Produce everything from concept models to functional parts

- Can connect directly to a PC workstation or be integrated into a network for pre-processing of the job files and for remote monitoring

- The system has a stand-alone PC, which allows it to work independently from the pre-processing workstation

Materials Available

-

ABS 3SP® Flex (Black, Gray, White): Models similar to ABS plastic with flexibility characteristics

-

ABS 3SP® White: Models similar to ABS plastic

-

ABS 3SP® Tough: Rigid, stable models similar to those made with ABS plastic

-

ABS 3SP® Superflex: Models similar to ABS plastic with flexibility characteristics

-

E-Denstone 3SP® Peach: General purpose, high temperature molding, concept models

-

E-Glass 3SP®: Strong, clear material with flexible capabilities

Machine Specifications*

-

Build Envelope: 10″ x 14.25″ x 13″ (254 x 362 x 330 mm)

-

Resolution in X and Y: 0.004″ (100µm)

-

Dynamic Voxel Resolution in Z**: 0.002″ – 0.004″ (50 – 100 µm)

*Specifications subject to change without notice.

** User adjustable – material dependent

System Properties

-

Footprint (L x W x H): 65” x 65” x 65” (165 x 165 x 165 cm)

-

Weight: 890 lbs (404 kg)

-

Electrical Requirements: 220 Volt, single phase, 15A

-

Data Handling – STL

-

Warranty – 1 year included on machine

System Data Handling

-

Can connect directly to a PC workstation or be integrated into a network for pre-processing of the job files and for remote monitoring

-

The system has a stand-alone PC, which allows it to work independently from the pre-processing workstation

EnvisionTEC 3D Industrial Printers Printers Spec Sheet Available through Rich Port 3D Solutions

Xede® 3SP® Ortho

EnvisionTEC’s Xede® 3SP® Ortho large format 3D printer allows for the production of orthodontic models, built at fast build speeds without sacrificing surface quality and part accuracy. The Xede® 3SP® Ortho uses EnvisionTEC’s 3SP® (Scan, Spin, and Selectively Photocure) technology to quickly 3D print highly accurate orthodontic models in large batch quantities. Each 3D printer is delivered and installed with all the relevant software to enable perfect model production from a wide range of orthodontic design software. The surface quality of the printed models show no signs of stairstepping on the inner and outer surfaces. The reliability of the light source and the high speed productivity of the Xede® 3SP® Ortho makes it one of the most competitive 3D printers on the market today.

Benefits:

- One single material is used for both build and easily removable, partially cured perforated supports

- Very few moving parts make system user-serviceable

- Low part cost due to minimal material waste

- Produce everything from concept models to functional parts

- Connect directly to a PC workstation or be integrated into network for pre-processing of job files and remote monitoring

- The stand-alone PC allows for working independently from pre-processing workstation

Materials Available

-

E-Denstone 3SP®: High quality orthodontic models

-

E-Appliance 3SP®: Models for orthodontic appliances

-

E-Denstone Tough 3SP®: High quality orthodontic models

-

Ortho Tough 3SP®: High quality orthodontic models

Machine Specifications*

-

Build Envelope: 18″ x 20″ x 4″ (457 x 508 x 102 mm)

-

Resolution in X and Y: 0.004″ (100µm)

-

Dynamic Voxel Resolution in Z**: 0.002″ – 0.004″ (50 – 100 µm)

*Specifications subject to change without notice.

** User adjustable and material dependent

System Properties

-

Footprint (L x W x H): 70” x 75” x 65” (178 x 190 x 165 cm)

-

Weight: 1245 lbs (565 kg)

-

Electrical Requirements: 220 Volt, single phase, 15A

-

Data Handling – STL

-

Warranty – 1 year included on machine

System Data Handling

-

Can connect directly to a PC workstation or be integrated into a network for pre-processing of the job files and for remote monitoring

-

The system has a stand-alone PC, which allows it to work independently from the pre-processing workstation

EnvisionTEC 3D Industrial Printers Printers Spec Sheet Available through Rich Port 3D Solutions

Xede® 3SP®

EnvisionTEC’s Xede® 3SP® large format 3D printer allows for production of exceptionally large 3D parts, built at fast build speeds without sacrificing surface quality and part accuracy. Xede® 3SP® 3D Printer uses EnvisionTEC’s 3SP® (Scan, Spin, and Selectively Photocure) technology to quickly 3D print highly accurate parts from STL files regardless of geometric complexity. Xede® 3SP® 3D Printer is delivered and installed with all the relevant software to enable automatic generation of supports and perfect model production. The surface quality of the printed models show no signs of stairstepping on the inner and outer surfaces. The reliability of the light source and the high speed productivity of these large format 3D printers make them some of the most competitive 3D printers on the market today.

Benefits:

- A single material is used for both build and easily removable, partially cured perforated supports

- Very few moving parts make the system user-serviceable

- Low part cost due to minimal material waste

- Produce everything from concept models to functional parts

- Can connect directly to a PC workstation or be integrated into a network for pre-processing of the job files and for remote monitoring

- The system has a stand-alone PC, which allows it to work independently from the pre-processing workstation

Materials Available

-

ABS 3SP® Flex (Black, Gray, White): Models similar to ABS plastic with flexibility characteristics

-

ABS 3SP® White: Models similar to ABS plastic

-

ABS 3SP® Tough: Rigid, stable models similar to those made with ABS plastic

-

ABS 3SP® Superflex: Models similar to ABS plastic with flexibility characteristics

-

E-Denstone 3SP® Peach: General purpose, high temperature molding, concept models

-

E-Glass 3SP®: Strong, clear material with flexible capabilities

Machine Specifications*

-

Build Envelope: 18″ x 18″ x 18″ (457 x 457 x 457 mm)

-

Resolution in X and Y: 0.004″ (100µm)

-

Dynamic Voxel Resolution in Z**: 0.002″ – 0.004″ (50 – 100 µm) – user adjustable

*Specifications subject to change without notice.

**Material dependent

System Properties

-

Footprint (L x W x H): 64” x 55” x 72” (163 x 140 x 183 cm)

-

Weight: 1500 lbs (680 kg)

-

Electrical Requirements: 220 Volt, single phase, 15A

-

Data Handling – STL

-

Warranty – 1 year included on machine

System Data Handling

-

Can connect directly to a PC workstation or be integrated into a network for pre-processing of the job files and for remote monitoring

-

The system has a stand-alone PC, which allows it to work independently from the pre-processing workstation

EnvisionTEC 3D Industrial Printers Printers Spec Sheet Available through Rich Port 3D Solutions

EnvisionTEC’s Xtreme® 3SP® and Xede® 3SP® large format 3D printers allow for production of exceptionally large 3D parts, built at fast build speeds without sacrificing surface quality and part accuracy. The Xtreme® 3SP® and Xede® 3SP® 3D Printers use EnvisionTEC’s 3SP® (Scan, Spin, and Selectively Photocure) technology to quickly 3D print highly accurate parts from STL files regardless of geometric complexity. The Xtreme® 3SP® and Xede® 3SP® 3D Printers are delivered and installed with all the relevant software to enable automatic generation of supports and perfect model production. The surface quality of the printed models show no signs of stairstepping on the inner and outer surfaces. The reliability of the light source and the high speed productivity of these large format 3D printers make them some of the most competitive 3D printers on the market today.

Find Your Xtreme® or Xede® 3SP® 3D Printer Now!

Xede® 3SP®

Xede® 3SP® Ortho

Xtreme® 3SP®

Xtreme® 3SP® Ortho

EnvisionTEC’s ULTRA® 3SP® 3D Printer Series uses ground-breaking 3SP® (Scan, Spin and Selectively Photocure) technology to quickly 3D print highly accurate parts from STL files regardless of the geometric complexity. The ULTRA® 3SP® and 3SP® High Definition 3D Printers are each delivered and installed with all the relevant software to enable automatic generation of supports and perfect model production. The surface quality of the printed models show no signs of stair-stepping on the inner and outer surfaces. The reliability of the imaging light source and the high speed productivity makes it the most competitive 3D printer on the market today.

Benefits

- A single material is used for both build and support

- Easily removable partially cured perforated supports

- Very few moving parts make the 3D printer system user serviceable

- Office friendly plug-and-play operation with a built-in touch screen

- Low part cost due to minimal material waste

- Produce everything from concept models to functional parts

- Layerless technology with no stair-stepping on inner and outer surfaces

- Quiet operation

Find Your ULTRA® 3SP® 3D Printer

3Dent™

ULTRA® 3SP®

ULTRA® 3SP® HD

ULTRA® 3SP® Ortho

EnvisionTEC’s Perfactory® 4 Standard 3D Printer Family are low cost, easy maintenance and user friendly 3D printers for rapid prototyping and rapid manufacturing. Using state-of-the-art Direct Light Projection technology from Texas Instruments®, the Perfactory® Standard 3D Printer Family produces the finest detail in the shortest period of time. It creates 3D models that range from the conceptual to the fully functional.

Benefits:

- Economic material use with no vat

- Very few moving parts and minimal consumable components make the system user serviceable

- Models are suitable for direct manufacturing through rapid casting

- A choice of high quality materials are readily available

- Material changeover can be done quickly and easily

Find Your Perfactory® Standard 3D Printer Family and see which one fits your needs.

Perfactory® 4 DSP

Perfactory® 4 DSP XL

Perfactory® 3 DSP

Perfactory® 4 Standard

Perfactory® 4 Standard XL

EnvisionTEC’s Perfactory® 4 Mini 3D Printers with ERM are low cost, easy maintenance and user friendly 3D rapid prototype manufacturing system. Using state-of-the-art Direct Light Projection technology from Texas Instruments®, the Perfactory® 4 Mini 3D Printer produces the finest detail in the shortest period of time. It creates 3D models that range from the conceptual to the fully functional.

Benefits:

- Build speed in constant through the build up to 1” (25 mm) at 0.0039” (100 µm) voxel thickness

- Economic material use with no vat

- Very few moving parts and minimal consumable components make the system user serviceable

- Changeover between materials is quick and easy

Find out which Perfactory® Mini 3D Printer matches your needs.

Perfactory® 4 DDP

Perfactory® 4 Mini

Perfactory® 4 Mini XL

Perfactory® 3 Mini Multi Lens

Perfactory® 3 DDP

The Perfactory® Desktop 3D Printer Family has an unbeatable price to performance ratio. The perfect choice for the small to medium sized company looking to fulfill their 3D printing production requirements. With the ability to run unattended, 24 hour production. Our 3D printers can run a variety of materials for direct casting, hot rubber, and silicone molding. There are no limits to geometric complexity as long as the item has been designed in a 3D CAD program and may be exported as an STL file. Our 3D printers are delivered and installed with all the relevant software to enable automatic support generation and perfect model production. Resolution and surface finish remains constant over the entire build area due to patented technology based on voxelisation.

Benefits:

- Easy handling through pre-adjusted material modules

- Very few moving parts and minimal consumable components guarantee a strong and reliable system

- Utilizing a built in ethernet interface, can connect directly to a PC workstation or be integrated into a network

- Changeover between materials is done quickly and easily

Find out which Perfactory® Desktop 3D Printer matches your needs.

Perfactory® Apollo

Perfactory® Aureus

Perfactory® PixCera

Perfactory® Desktop Digital Dental Printer (DDDP)

Perfactory® Mini DDSP

Perfactory® Desktop Digital Shell Printer (DDSP)

Perfactory® Desktop XL