Tuesday

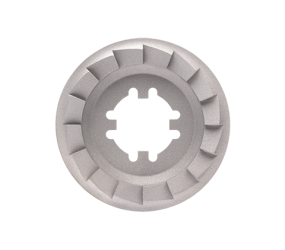

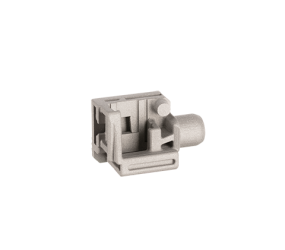

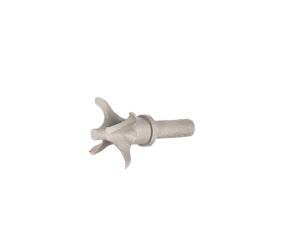

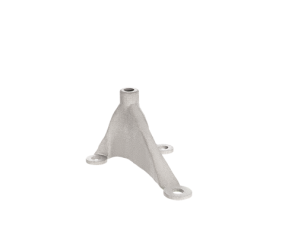

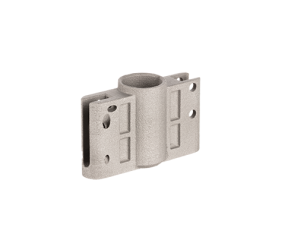

Metal 3D printing for the automotive industry

8AM ET

For the automotive sector, metal 3D printing offers dramatic productivity benefits in several key areas. Join this webinar on how the automotive sector is turning to metal 3D printing to create better products and deliver them to the market sooner and more efficiently.

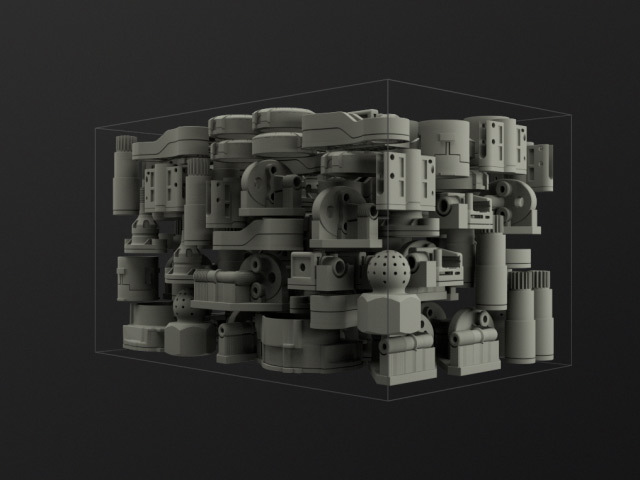

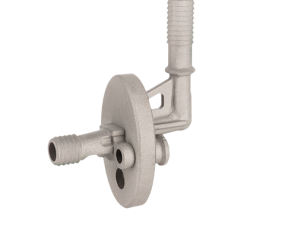

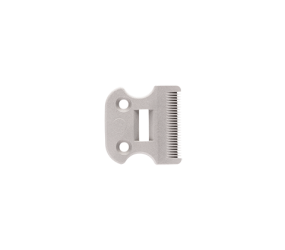

Final part properties of metal printed parts

1PM ET

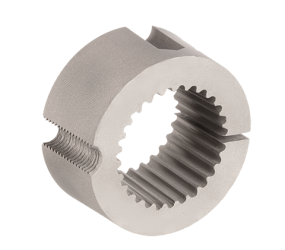

Desktop Metal’s printing systems are built around the chemistry and powder supply chain of metal injection molding, a widely accepted and validated powder metallurgy process that enables the fabrication of complex parts with great properties. Join this webinar to learn about Desktop Metal’s material development process

Wednesday

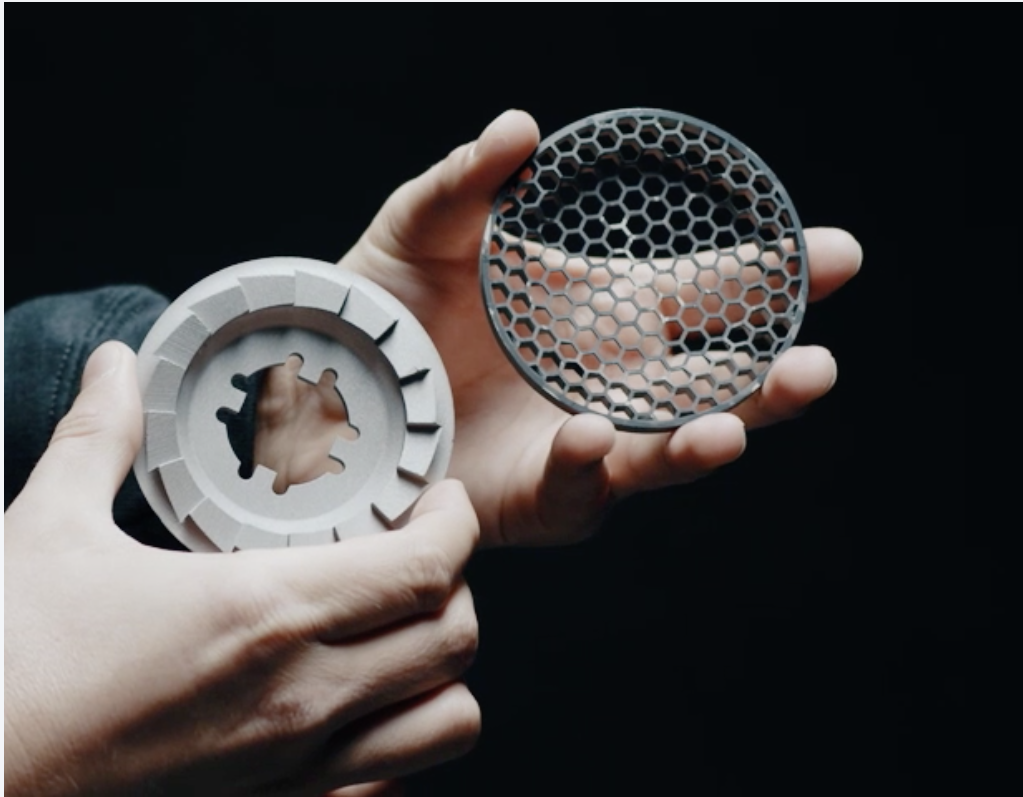

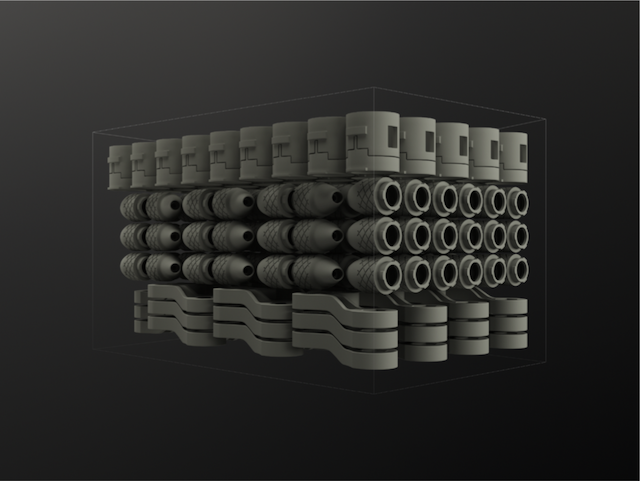

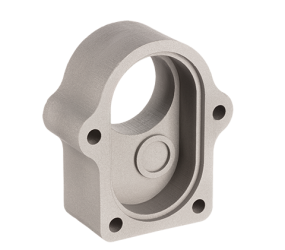

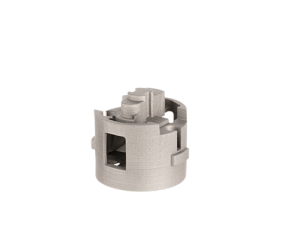

Introduction to the Studio System

8AM ET and 1PM ET

Discover how the Studio System can help drive efficiencies and new opportunities for your business with prototyping and low volume production via metal 3D printing.

Thursday

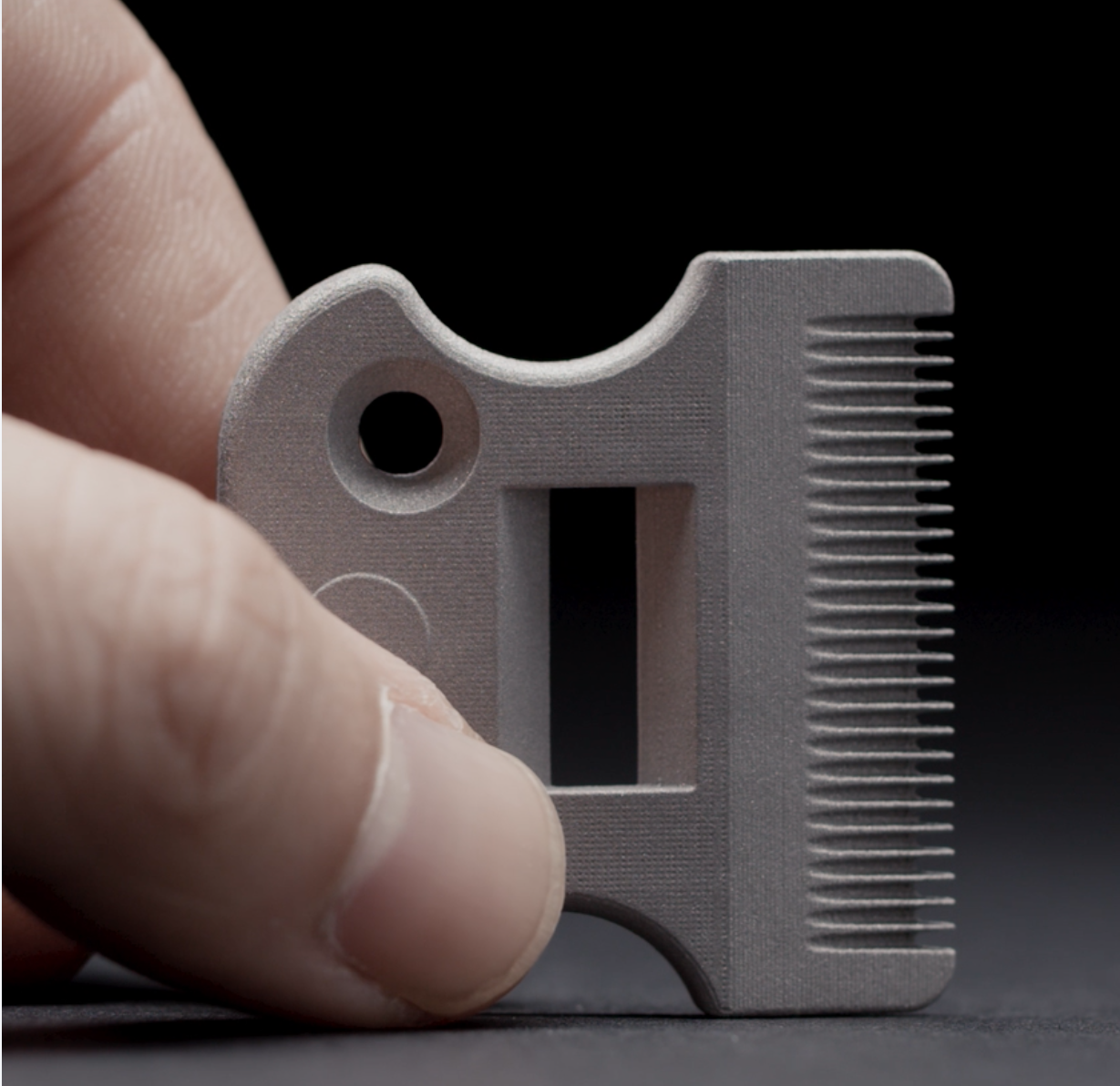

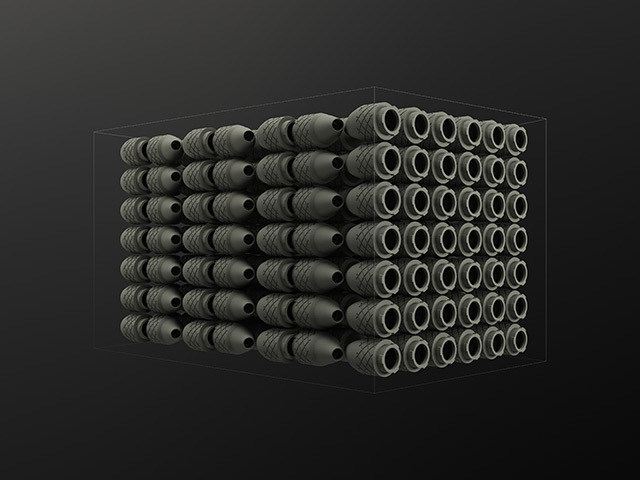

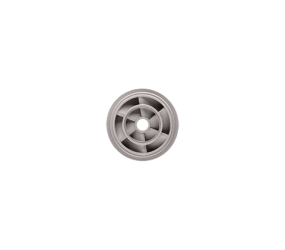

Introduction to the Shop System

8AM ET and 1PM ET

The Shop System is the world’s first metal binder jetting system designed for machine shops. It is designed to seamlessly integrate into a machine shop’s workflow and make it possible to cost effectively print end-use metal parts. Learn more in this webinar.

Final part properties of metal printed parts

11AM ET

Desktop Metal’s printing systems are built around the chemistry and powder supply chain of metal injection molding, a widely accepted and validated powder metallurgy process that enables the fabrication of complex parts with great properties. Join this webinar to learn about Desktop Metal’s material development process

Friday

Introduction to Fiber

8AM ET and 1PM ET

Fiber offers the ability to 3D print industrial-grade composite structures, featuring continuous fiber tapes for unrivaled part strength. In this webinar, learn about the technology, materials and applications for this printer.