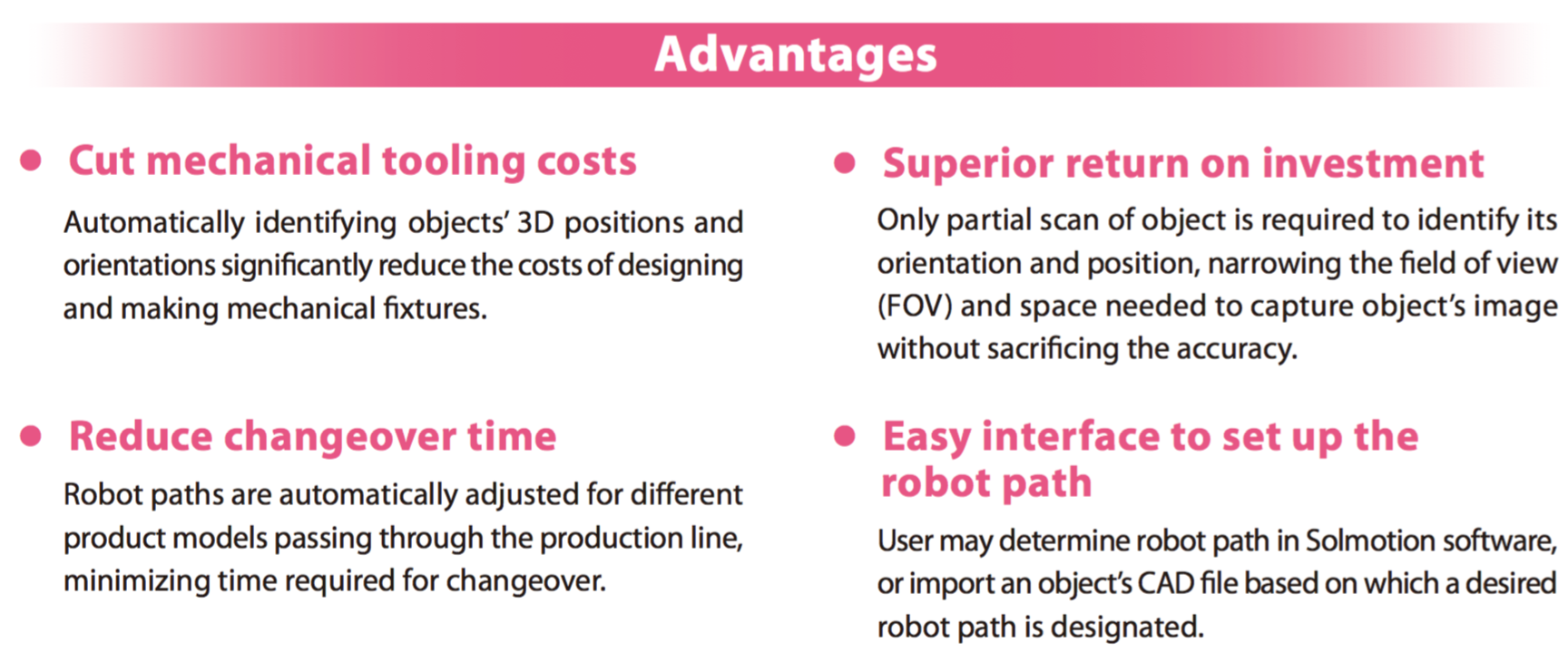

Solmotion is Vision Guided Robot Motion (VGR/VGM).

Leveraging the power of 3D vision and AI technologies, Solomon VGR/VGM (Vision Guided Robot/Motion) takes robot motion planning development to the next level by boosting robots′ capabilities, by providing them with “eyes” which allow a quick and accurate identification of an object positions and orientations. With Solomon VGR/VGM, robots are able to perform tasks without having to set an object′s position through a mechanical fixture.

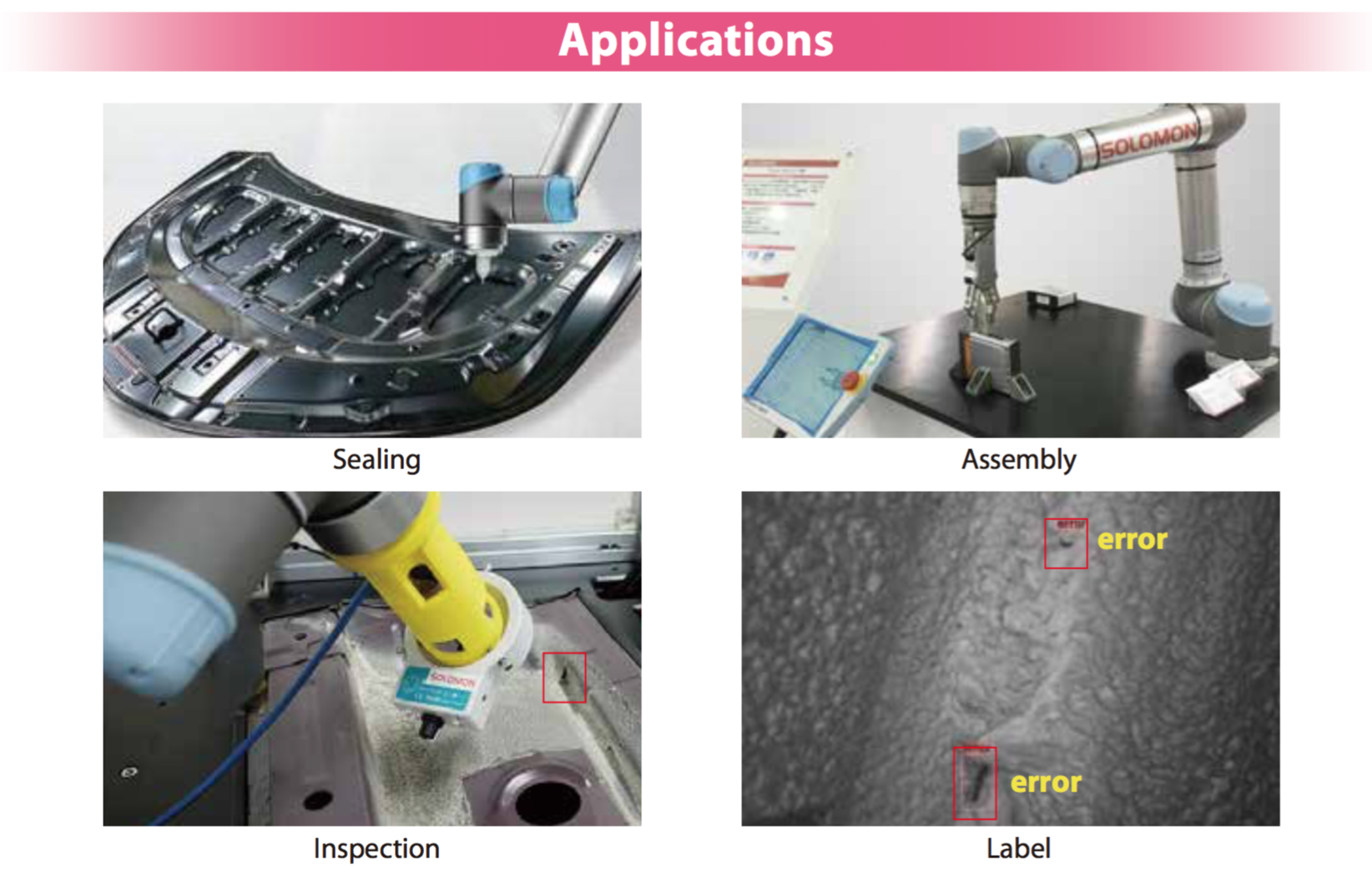

Solmotion blends 3D vision and machine learning to enhance manufacturing flexibility and productivity. Solmotion intelligently identifies work pieces randomly placed, pinpoints their positions and orientations, then commands robot to carry out specific tasks with high tracking accuracy. 3D vision guided robot (VGR) can be used for applications including sealing, inspection, welding, assembly, labeling, among others.

Download Solmotion Brochure Here

SOLMOTION Enables Robot to Glue Car Hood

SOLMOTION's uses Solomon 3D scanner and path planning software to enable this robot to glue a car hood. The 3D vision system automatically recognizes the orientation of the engine′s hood and adjusts the robot path accordingly. Unlike other vision software, there is no need to mechanically fix the object′s position.

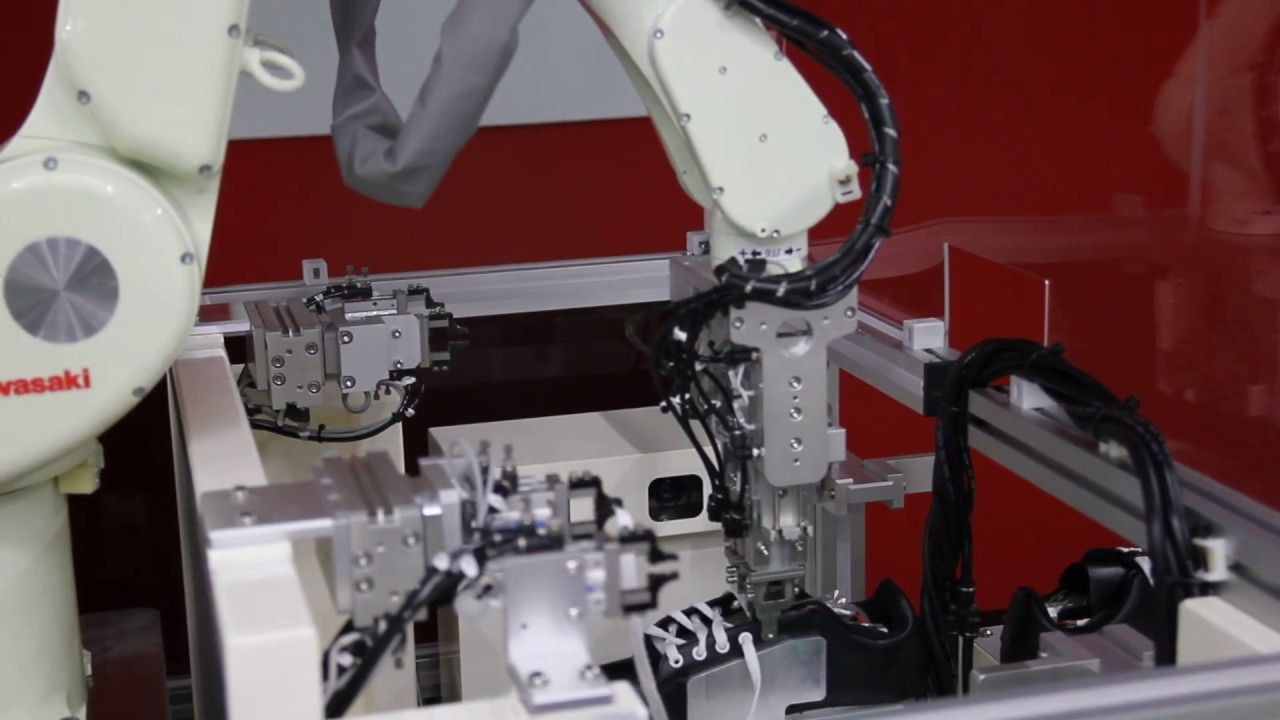

World's First Automated Shoe Lacing Machine

Robotic lacing is widely considered as a challenging task in the shoe industry. This patented shoe lacing machine uses SOLOMON 3D vision to enable a Kawasaki robot arm to go through the eyelets. The Robot is given the "vision" neccesary to find the eyelets even if they are positioned differently among shoes of the same size and design model.

SOLOMON Vision Enbales Robot to De-rack

This robot can accurately carry out the unloading of bobbins from the holding rack to the next automation station because of SOLOMON Vision reproducibly provides it "vision" with +/-3mm accuracy. The 3D Vision system includes a Solomon 3D camera that is mounted on the end axis of this robot's arm, allowing it to scan the bobbin. Then the SOLOMON 3D Vision's artifcial intelligence recognition system recognizes the bobbin location enabling the robot to pick it up to be placed at the next automation station.

SOLOMON 3D VISION MADE SIMPLE available in the Caribbean through Rich Port 3D Solutions.

Contact Rich Port 3D Solutions for a Proof of Concept.