Solvision performs defect and pattern inspections with AI.

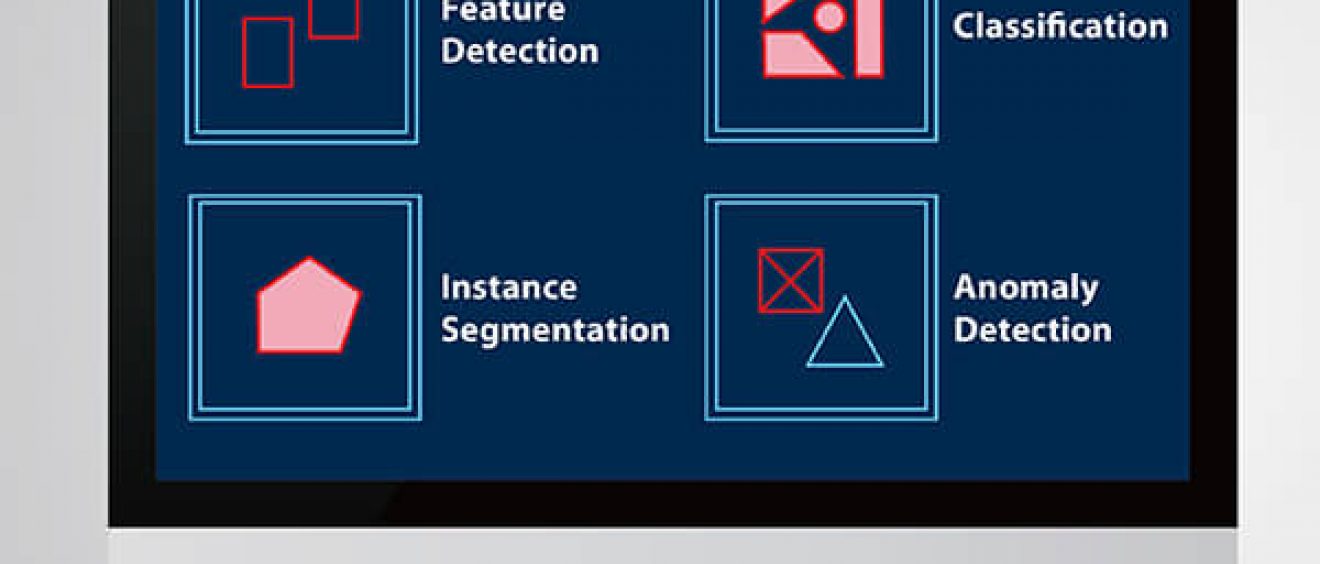

Solvision offers a simple and intuitive tool to solve complex machine vision problems. The software, built on layers of advanced neural networks, is best used to recognize irregular patterns and features. Detecting defects such as stains, scratches, burrs, cracks, identifying missing components or items, or sorting similar looking objects are examples of applications easily manageable using Solvision.

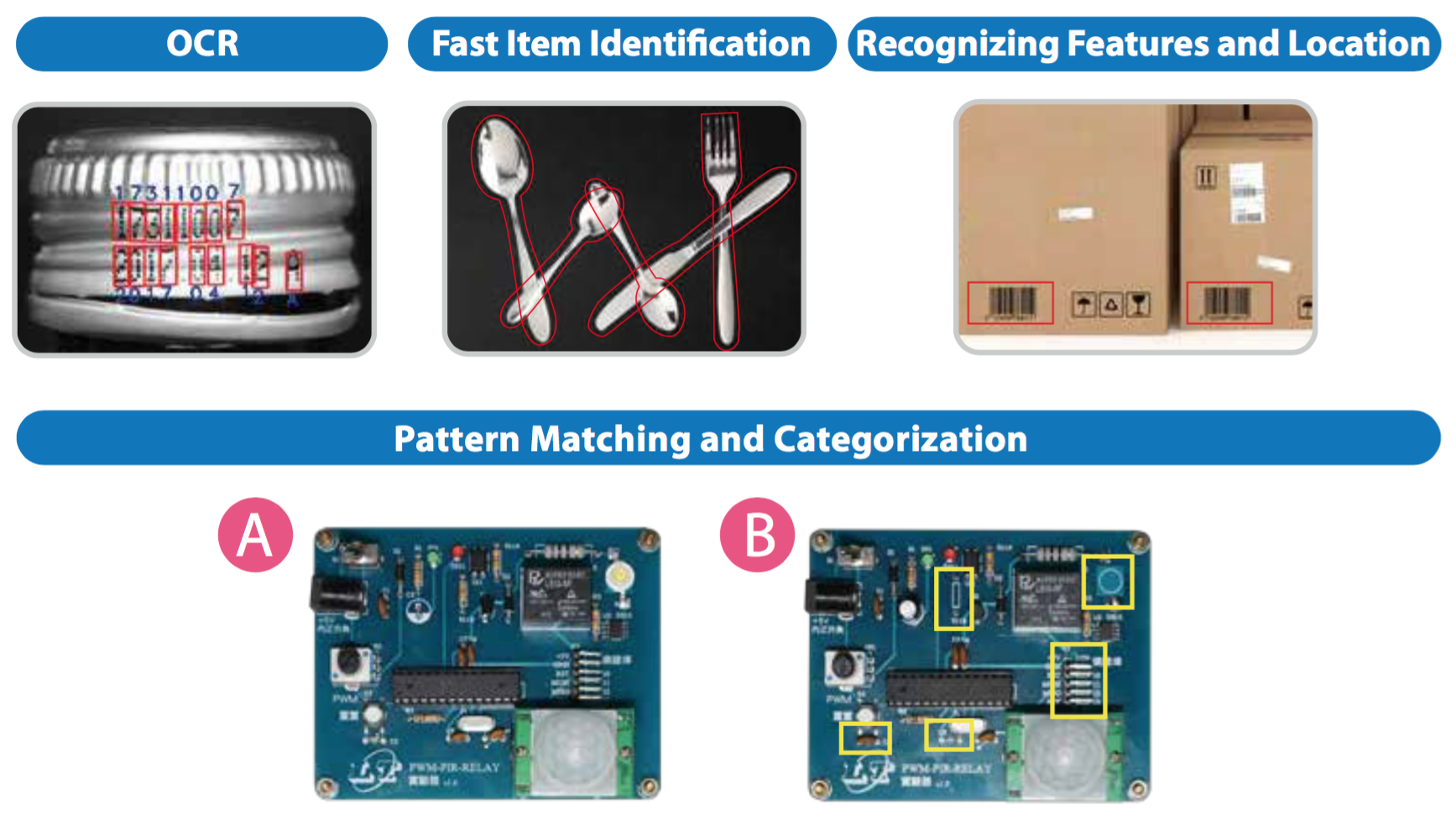

SOLOMON Machine Vision Reads Highly Deformed Characters

Highly deformed characters inked on a bottle cap need to be identified at a speed of 10 bottles per second. SOLOMON Machine Vision's uses deep learning and only a small number of samples for training, the characters are then instantly identified thus adding value to our cusomer's production line.

SOLOMON'S Machine Vision can be Trained and Running Quckly

Images of defect-free PCBs (GS) are used as a training set and input into Solomon´s Machine Vision Artificial Intelligence (AI) inspection software. Unlike in conventional automated optical inspection (AOI), it´s not necessary to write a code or train it with images containing individual defects. The Inspection software can be trained and running in a fraction of the time.

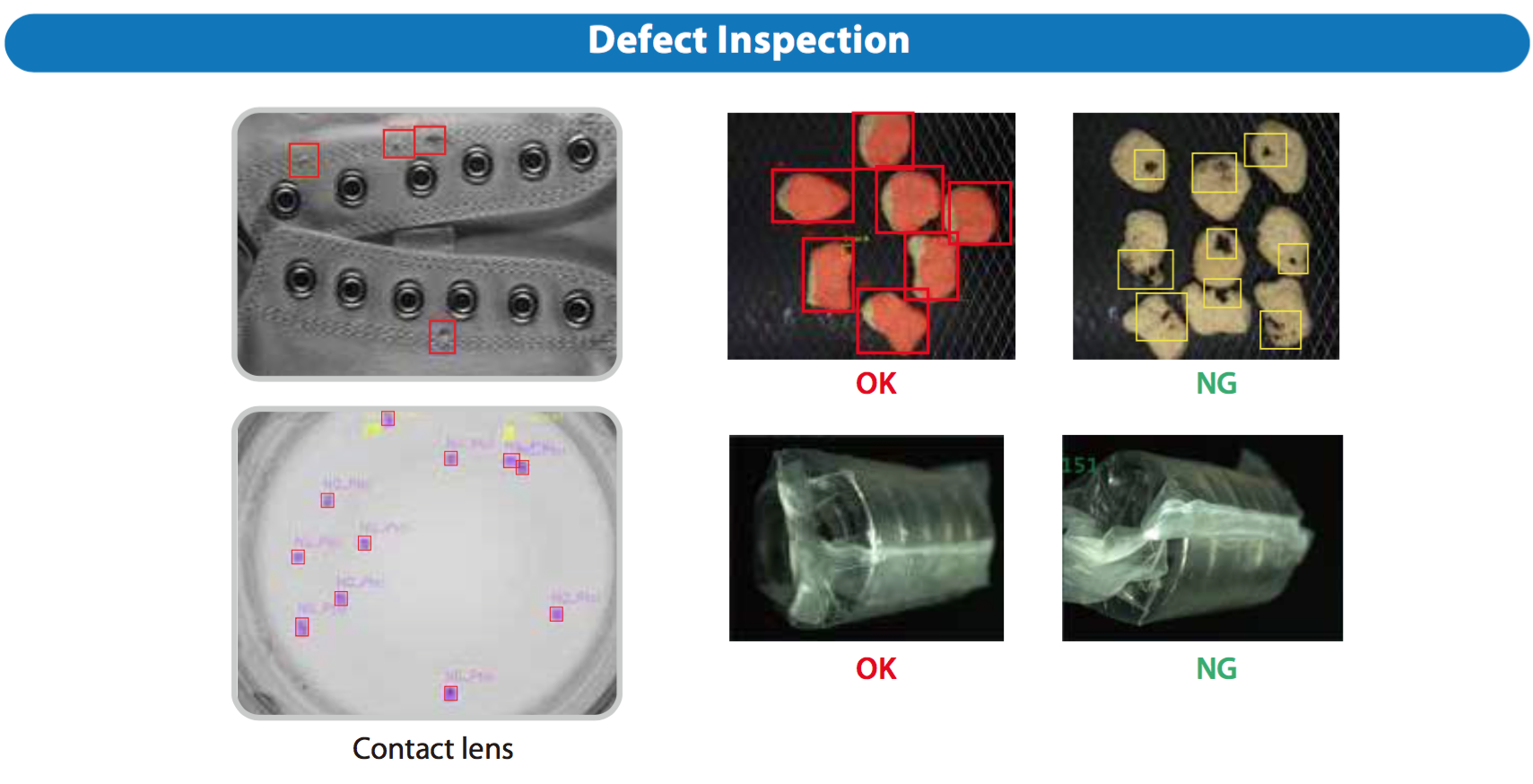

SOLOMON Machine Vision Inspects and Identifies Defects

Using Solomon´s Machine Vision deep learning software various defects on a shoe can be inspected and identified in real time. These imperfections can include but are not limited to stains, scratches, over cementing, and any other irregular features. SOLOMON Machine Vision only requires a small number of defective samples for training purposes. Your inspection system will be trained and operational in no time.

SOLOMON Machine Vision Identifies Fabric Blemishes

SOLOMON Machine Vision Identifies bar shaped white marks on a piece of fabric rapidly and easily using deep learning and a small number of samples. SOLOMON Machine Vision can also quickly be taught to indentify other defects such as marks, oil stains and holes through short training sessions. SOLOMON Machine Vision gives your inspection the flexibility it needs to compete.

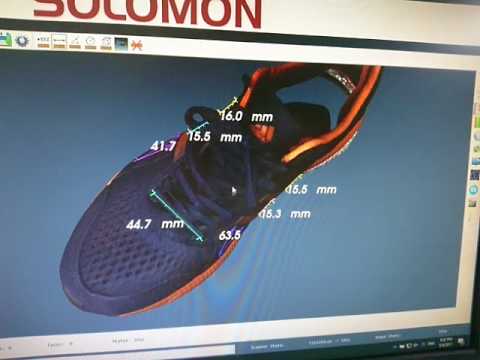

SOLOMON Machine Vision Scans and Measures Shoes

A robot with Solomon 3D scanner takes several 3D images of a shoe and stitches the images together. The resulting point cloud can be used to measure any dimensions or point-to-point distances on the scanned object (this can be done faster by using multiple scanners).

SOLOMON 3D VISION MADE SIMPLE available in the Caribbean through Rich Port 3D Solutions.

Contact Rich Port 3D Solutions for a Proof of Concept.

Download AccuPick Brochure Here