3D-BIOPLOTTER® MANUFACTURER SERIES

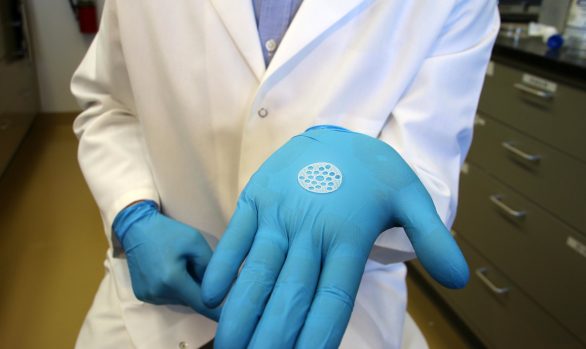

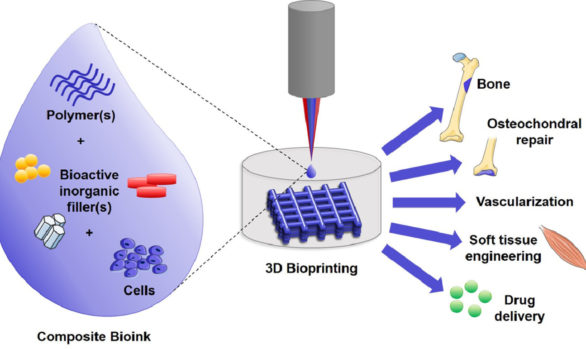

Envisiontec Bioplotter.2With three levels of functionality — Starter, Developer and Manufacturer — this family of bioprinters, processes open-source biomaterials using air or mechanical pressure to a syringe, which can fabricate scaffolds to create tissue, organs and more. Our bioprinters are extremely accurate with X-Y repeatability down to 1 μm. All models have been designed for use in a sterile biosafety cabinet, meet standards for clinical trials and offer build sizes up to 192.4 cubic inches.

Developed at the University of Freiburg, the bioprinting technology used by the 3D-Bioplotter allows for maximum flexibility for research and development. The system uses modular components, such as sterilized heating and cooling cartridges, standard Luer-Lok syringes with standard needle-tip sizes and an easy-to-use 365 nm UV curing head. “It’s a popular tool because it’s a very flexible, but also user-friendly machine,” -Carlos Carlvalho, Envisiontec Material Development Engineer. The software also allows for maximum freedom in combining different materials using different temperatures.

The machine features vary between the levels of functionality. For example, the Manufacturer model allows for 5 print heads and also includes a heated platform and sterile filter, which is recommended for cell and organ printing.

The 3D-Bioplotter family is also made with high-quality components and is extremely reliable, allowing R&D to spend more time printing. It is the STANDARD for Ground Breaking Bioprinting Research.