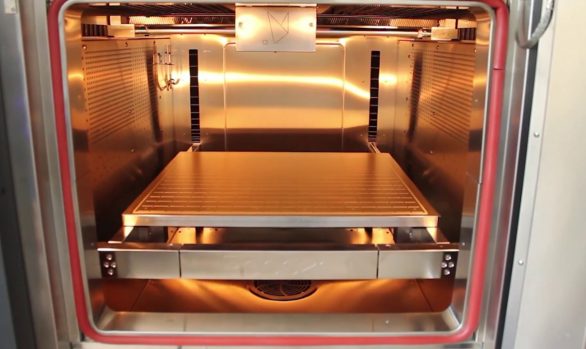

Extrusion system

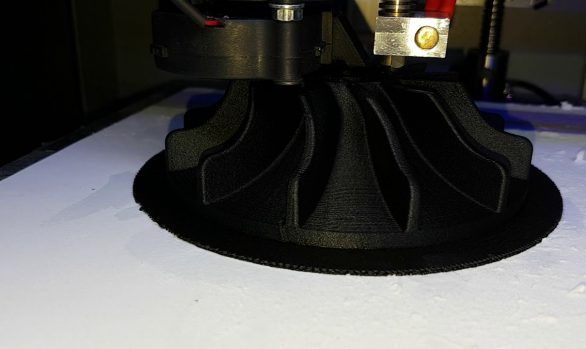

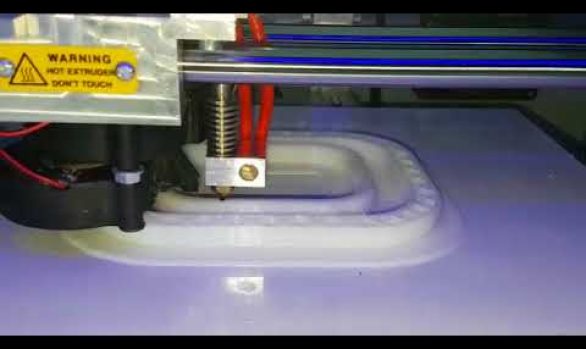

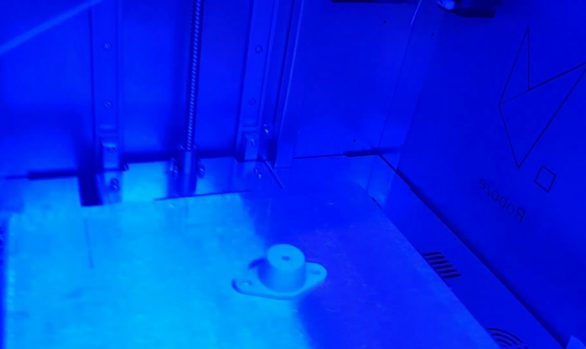

ARGO 500 VIDEOSThe Argo 500 solution can process super polymers and composite materials such as PEEK, Ultem and Carbon PEEK. This is done through our patent pending extrusion system called HVP Extruder, a device designed to facilitate the printing of high viscosity polymers. The compressed air cooling system allows you to manage long prints with extrusion temperatures up to 450 ° C, ensuring low dimensional tolerances and reducing the shrinkage phenomena of the material. The extruders are powered by a closed system, promptly cooled and consisting of two gears for pulling the filament, treated to resist wear and heat. This is a state-of-the-art feeder that guarantees excellent grip for all materials and a pulling force 10 times greater than that generated by traditional systems. The result is an optimized polymer flow, even when extruding a high viscosity material with 0.4mm nozzle, for unprecedented print quality.