What kind of parts can I make?

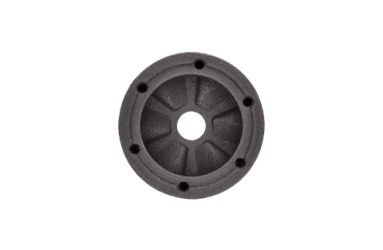

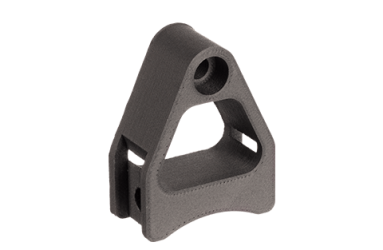

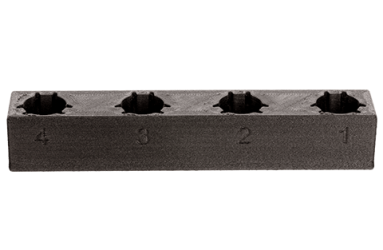

Parts can be 3D printed that span a variety of industries including manufacturing, tooling, automotive, consumer, electronics, marine and more. If you own a small machine shop you can start to provide high performance customized parts such as CNC fixtures (see below). If you already sell automotive parts you can expand your offering to include customized parts such as exhaust heat shields (see above). If you have a hardware store you can compete with Home Depot by offering customized tools such as mirror and camera mounts (see below). If you are an engineer at a manufacturing plant you can produce parts such as end-of-arm tooling, including those used in electronics manufacturing (see below).

The Desktop Metal Fiber™ printer come in two flavors: Fiber™ LT & Fiber™ HT

- Micro Automated Fiber Placement (μAFP) and Fused filament fabrication (FFF) print technology.

- Standard configuration: 1 FFF head + 1 μAFP head

- Build Space: 310 x 240 x 270 mm (FFF only)

- Build Space: 290 x 210 x 270 mm (μAFP-reinforced)

- Layer height of 50-200 μm

- Maximum build rate of 20 cm3/hr

- Maximum Build Weight: 10kg

- Printhead Nozzle Diameter: 0.40 mm

- FFF build media: Thermoplastic filament / Chopped fiber 1.75 mm diameter

- μAFP build media: Thermoplastic μAFP prepreg tape / Continuous fiber 3 mm wide

- Reinforcement: Automated optimization

- Compatible materials: PA6 + CF, PA6 + FG

- Starter Material Included

- Ability to upgrade your printer at anytime to a higher or newer model

- Box for drying filament prior to printing to maximize success.

- State-of-the-art, cloud-based software for print preparation which includes cloud-based new releases and software updates.

- Desktop Metal has online resources that will provide you with guides for installation, operation, and troubleshooting.

- If you are uncertain about your Fiber™ Printer or Fabricate™ Software performance, or you have any questions or concerns, the Desktop support team is here to help you over the phone, email, or chat.

- Micro Automated Fiber Placement (μAFP) and Fused filament fabrication (FFF) print technology.

- Standard configuration: 2 FFF head + 1 μAFP head

- Build Space: 310 x 240 x 270 mm (FFF only)

- Build Space: 290 x 210 x 270 mm (μAFP-reinforced)

- Layer height of 50-200 μm

- Maximum build rate of 20 cm3/hr

- Maximum Build Weight: 10kg

- Printhead Nozzle Diameter: 0.40 mm

- FFF build media: Thermoplastic filament / Chopped fiber 1.75 mm diameter

- μAFP build media: Thermoplastic μAFP prepreg tape / Continuous fiber 3 mm wide

- Reinforcement: Automated optimization, Custom targeted reinforcement

- Compatible materials: PEEK + CF, PEKK + CF, PA6 + CF, PA6 + FG

- Starter Material Included

- Ability to upgrade your printer at anytime to a newer technology model

- Box for drying filament prior to printing to maximize success.

- State-of-the-art, cloud-based software for print preparation which includes cloud-based new releases and software updates.

- Desktop Metal has online resources that will provide you with guides for installation, operation, and troubleshooting.

- If you are uncertain about your Fiber™ Printer or Fabricate™ Software performance, or you have any questions or concerns, the Desktop support team is here to help you over the phone, email, or chat.

- PA6 Chopped Fiberglass

- PA6 Chopped Carbon Fiber

- PEEK Chopped Carbon Fiber

- PEKK Chopped Carbon Fiber

- PA6 Continuous Fiberglass

- PA6 Continuous Carbon Fiber

- PEEK Continuous Carbon Fiber

- PEKK Continuous Carbon Fiber

787.645.3041

CALL TODAY FOR A FREE CONSULTATION