SOLOMON AccuPick Action Video Gallery

Solomon AccuPick Enables Any Robot to Bin Pick

This is an example of random bin picking of automotive components using SOLOMON AccuPick based on Solomon´s 3D scanner and artificial intelligence software. Our System is connected to a Kawasaki 5kg robot and enabled it to successfully distinguish between the front and back sides of the objects and separately sort them.

AccuPick Random Bin Picking Small Parts

Solomon AccuPick 3D offered our customer a single software package that was able to recognize 50+ different parts in a working station. Using the power of our AI software, AccuPick 3D helped their riobot to recognize a 5mm sized washer, even when there were overlapping washers. Being able to recognize pieces of such small size has always been a challenging task for other 3D vision solutions, but SOLOMON AccuPick 3D effectively solves this problem by relying on a single vision software that allows it to fulfill the needs of our customers, helping them to lower operational costs and maximize profits.

SOLOMON AccuPick Quickly Learns About Your Complex Shapes

This robot run with SOLOMON AccuPick is trained to pick complex shaped objects using AccuPick's deep learning ability combined with 3D vision. The unique ability to learn without a previosly uploaded CAD file to match the object´s 3D shape significantly reduces the learning time compared to the conventional template matching methods of other machine vision solutions.

SOLOMON AccuPick Enabled a UR5 Robot Pick Small Pieces

This UR5 robot using SOLOMON AccuPick's 3D Vision can pick M4 sized black screws that have been randomly placed in a bin. The Accupick recognizes part orientation so the robot can accurately pick up screws.

SOLOMON AccuPick 3D Easily Recognizes Object Orientation

SOLOMON AccuPick 3D vision system connected to this robot is trained to recognize an object´s orientations using deep learning technology. The ability to "see" the object's orientation enabled the gripper on this robot to efficiently pick M3 screws from the bin.

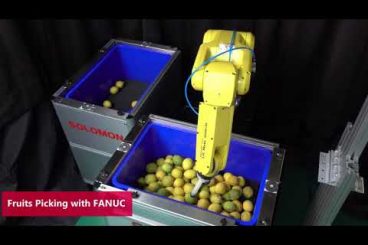

AccuPick Bin Fruit Picking for Food Industry

Irregularly shaped objects are notoriously difficult to identify using conventional pattern matching techniques. By harnessing the strengths of deep learning to “identify” the different features of an object, SOLOMON Accupick enabled this robot to automate fruit picking effectively for our customer.

SOLOMON AccuPick Enabled a UR5 Robot Pick and Place

This UR5 robot using SOLOMON AccuPick's 3D Vision with artificial intellegience can pick round shaped metal pieces that have been randomly placed in a bin and then insert them into a molding machine with synchronization of the control systems.

SOLOMON AccuPick 3D Enables Yaskawa Motoman to Pick and Sort

SOLOMON AccuPick 3D connects to this Yaskawa robot and enabled it to pick metal objects by distinguishing between front and back sides. In this case bin collision avoidance software was included to prevent the robot and gripper from colliding into the bin.

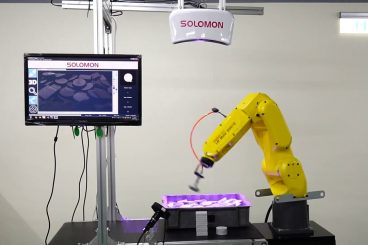

SOLOMON AccuPick Enabled FANUC Robot to Pick and Sort

This robot using SOLOMON AccuPick is trained to pick and sort between two different items using our 3D scanner and Accupick's artificial intelligence software, along with a 2D camera for stacking alignment. For this demonstration, a Fanuc robot with a payload of 7kg was used. SOLOMON AccuPick connects to ANY Robot.

SOLOMON AccuPick Enables Robot to Sort and Classify between Slightly Different Colors

This robot using SOLOMON AccuPIck 3D Vision can sort and classify boxes with slightly different colors by using the most advanced deep learning technology and 3D vision.

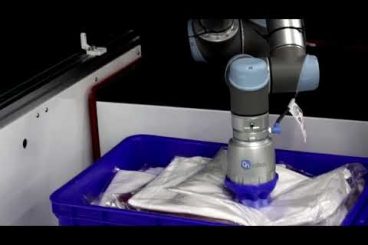

SOLOMON AccuPick Enables UR5 Robot to Pick Packages between Different Shapes & Sizes

Using Solomon’s AccuPick 3D this robot is able to pick apparels of various sizes and colors placed randomly in a bin. No prior learning of the individual apparel items is required, the system automatically picks them using the brand new Soft Gripper from OnRobot and UR5 cobot. This easy-to-use 3D vision package compatible with all available commercially robots is allows any sorting facility to build a picking station

SOLOMON Vision Enables Robot to De-rack Spools

This robot can accurately carry out the unloading of bobbins from the holding rack to the next automation station because of SOLOMON Vision reproducibly provides it "vision" with +/-3mm accuracy. The 3D Vision system includes a Solomon 3D camera that is mounted on the end axis of this robot's arm, allowing it to scan the bobbin. Then the SOLOMON 3D Vision's artifcial intelligence recognition system recognizes the bobbin location enabling the robot to pick it up to be placed at the next automation station.

SOLOMON AccuPick Enables Robot to Pick Up Randomly Placed Boxes and Sorts

SOLOMON AccuPick connects to this Robot and enables it to pick randomly placed boxes and then sort them based on labeled information.

First-The Proof of Concept Process

- Contact Us to be connected to a local consultant.

- Provide our consultant with details of your project.

- Provide our consultant with sample parts for a Proof of Concept in Action Video.

- Our cosultant will deliver the Proof of Concept in Action Video and Analysis to you for review.

Turn around time for AccuPick Proof of Concept ~1 week.

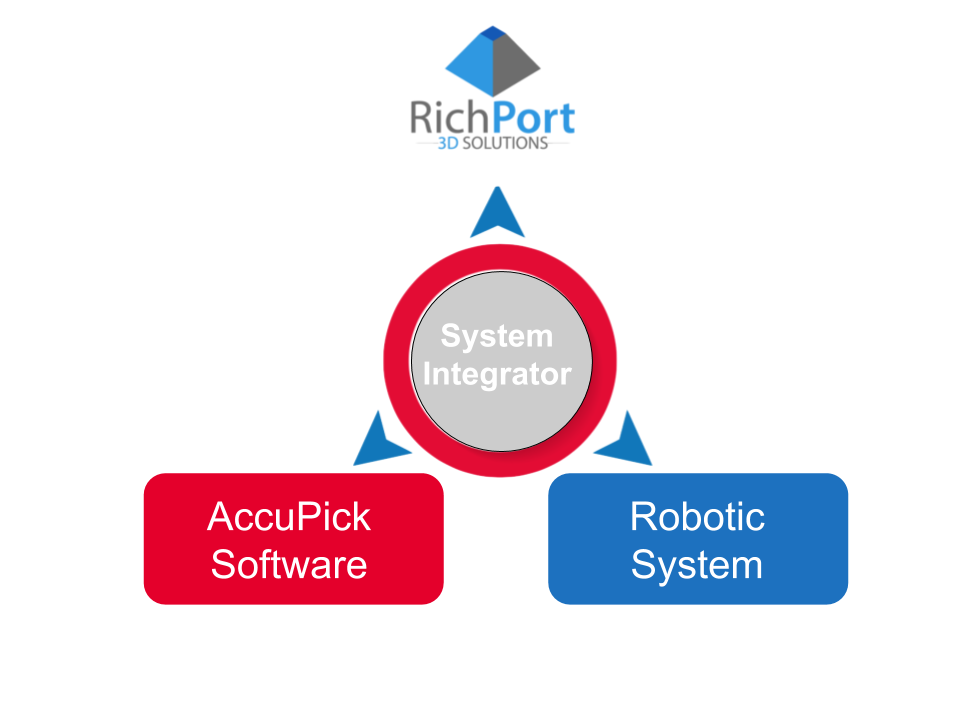

Second-We Connect You To A System Integrator