Desktop Metal Fiber™ Available in the Caribbean

Industrial Grade Continuous Fiber Composites can now be printed on a Desktop 3D Printer

Why are Industrial Grade Continuous Fiber Composites important?

Industrail Grade Continuous fiber composites are an array materials that can be stronger than steel at lesst than half the weight.

What is Desktop Metal Fiber™?

The Desktop Metal Fiber™ is a desktop printer from Desktop Metal that makes industrial grade thermoplastic composites with continuous fiber tape with unrivaled desktop 3D printed part strength. Desktop Metal Fiber™ 3D Printer exponentially expands the material performance landscape of 3D printed parts by a factor of over 60x. It enables the production of stronger, lighter-weight 3D printed parts at accessible pricing.

What makes constinous fiber thermoplastic composites so strong?

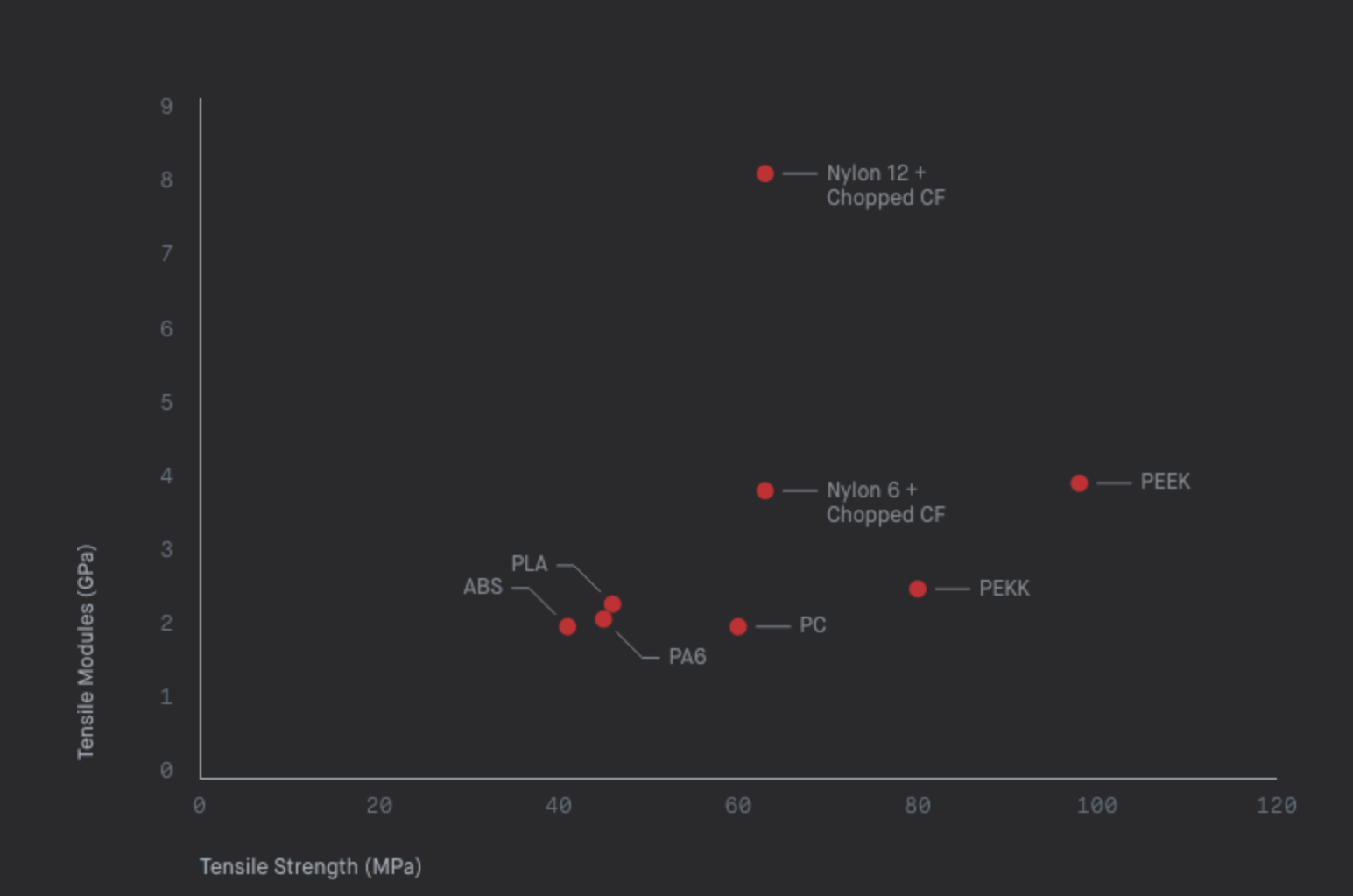

Thermoplastics (without composites) are plastic polymer materials that become soft when they are heated and return to rigidity when they cool. Fused filament fabrication (FFF) 3D printers typically use thermoplastics such as ABS, PLA and Nylon. There are also FFF 3D printers with high temperature printheads that print in PEEK and PEKK, both materials which have greater tensile strength. However, the enhancements in tensile modulus and tensile strength obtained by alternating between the different available thermoplastics falls within a relatively narrow range. All of them are roughly less than 8GPa tensile modulus and less than 100 MPa in tensile strength. These only account for a small fraction of the engineering needs.

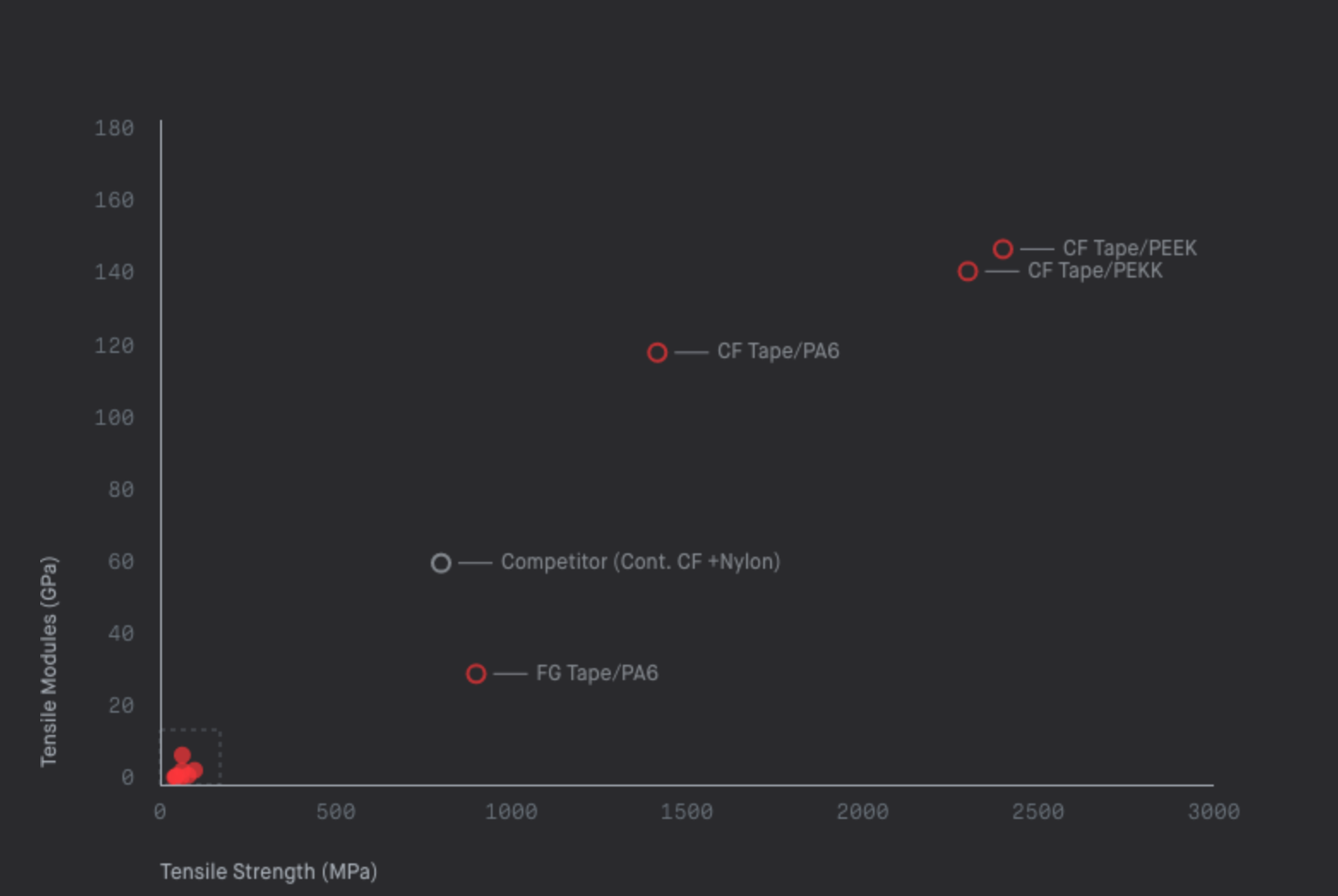

Thermoplastic composites with continuous fibers change the game completely. A thermoplastic composite has a thermoplastic matrix that has been reinforced with fibers such as carbon or glass. This reinforcement can happen one of two ways: using chopped fibers or continuous fibers. In the above graph it can be seen that nylon 6 and nylon 12 reinforcement with chopped carbon fiber has higher tensile modulus but nothing above 8 GPa. When you look at the tensile modulus and strength of thermoplastics reinforced with continuous glass and carbon fibers tape there is no comparison. Additive Manufacturing with thermoplastics reinforced with continuous fiber tape expands this tensile modulus and strength landscape (see small square in left hand corner) considerably to enable stronger, lighter-weight components. Desktop Metal Fiber™ 3D Printer exponentially expands the material performance landscape of 3D printed parts by a factor of over 60x. It enables the production of stronger, lighter-weight 3D printed parts at accessible pricing.

How Desktop Metal Fiber™ able to print high performance parts?

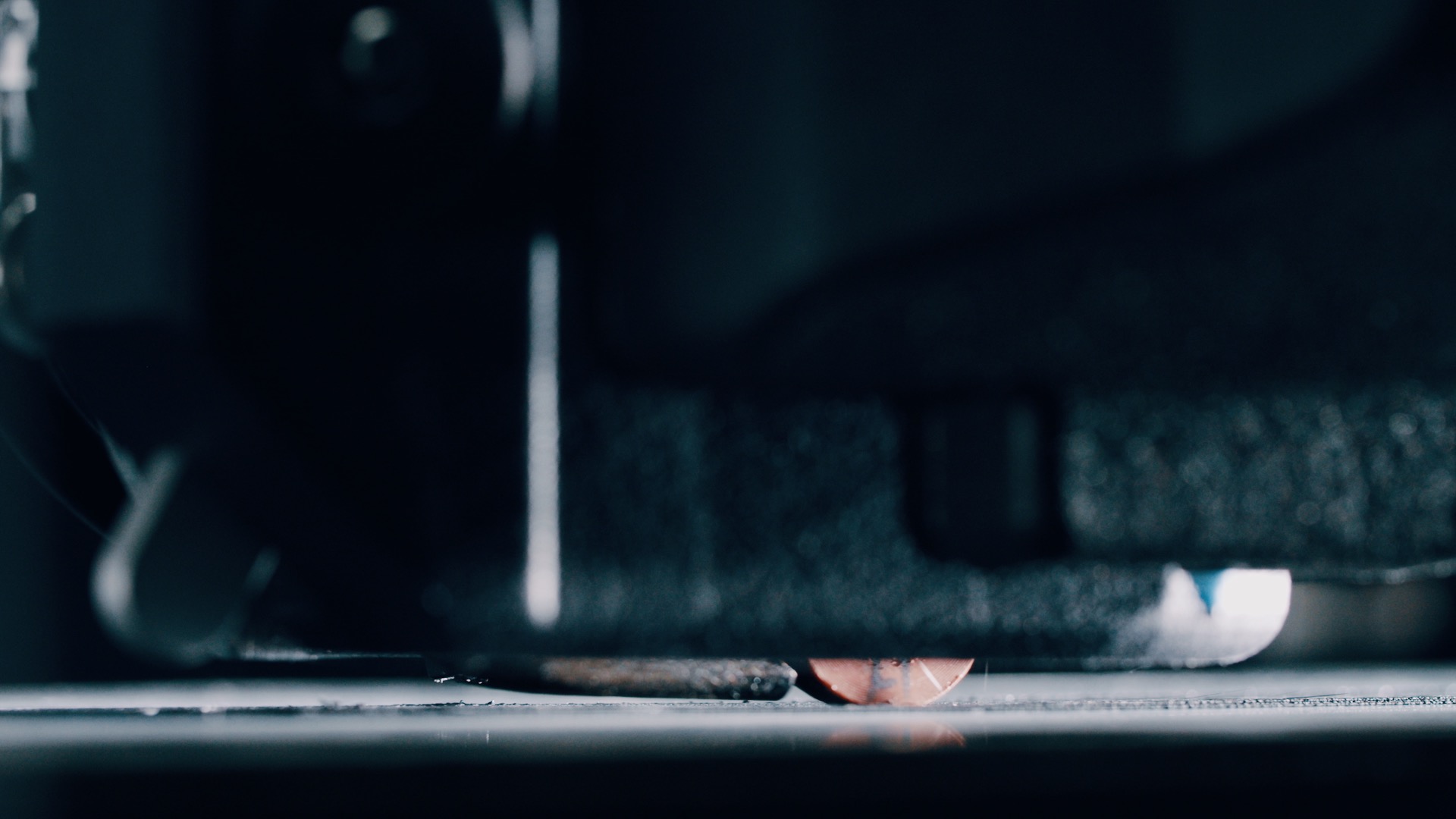

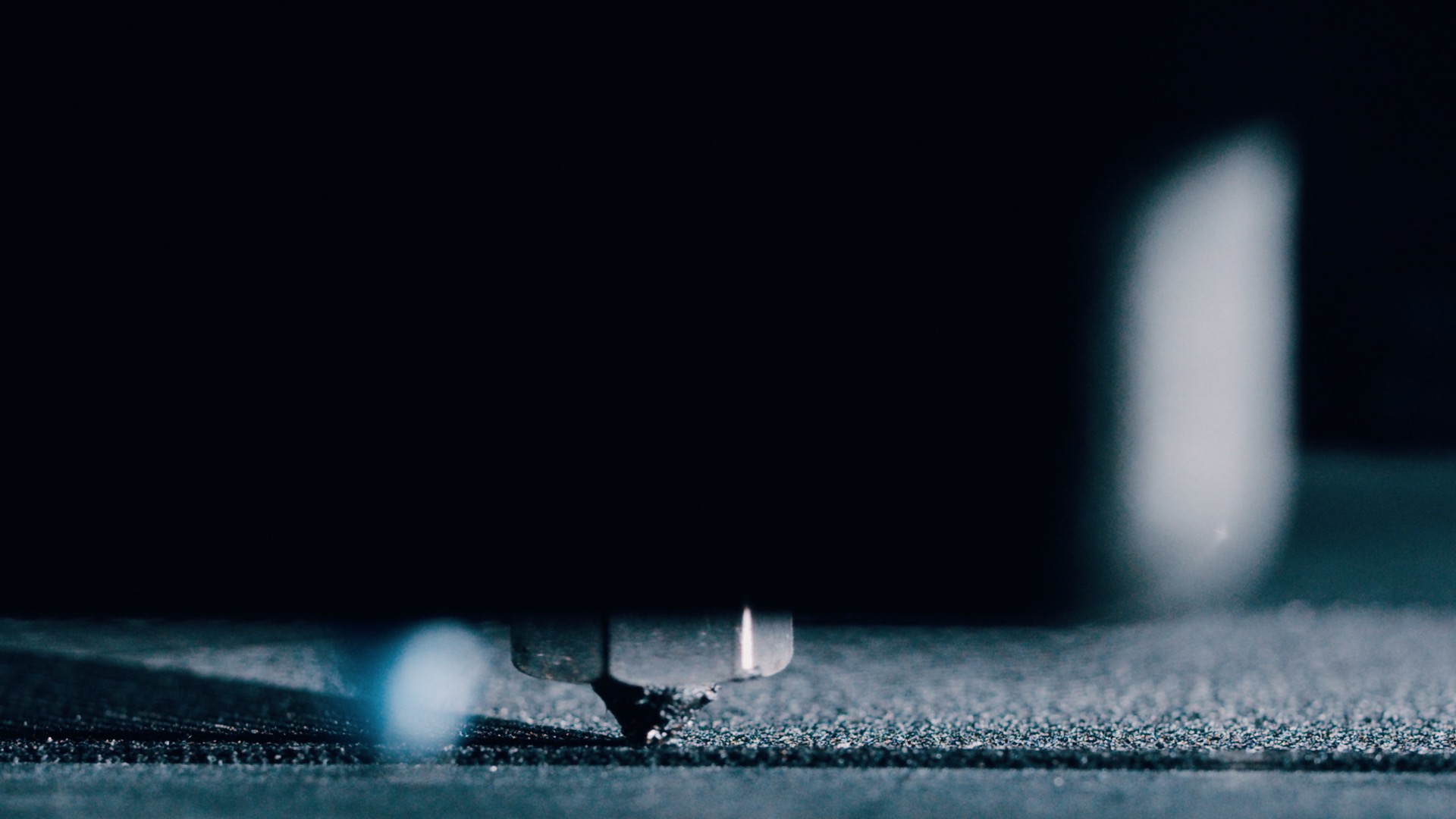

Desktop Metal Fiber™ combines the exceptional performance of continuous fiber with the ease of FFF printing to produce high-performance parts that are stronger than steel, lighter than aluminum, and can operate continuously in the toughest environments up to 250 ºC. It uses a combination of chopped fiber filaments and contiuous fiber tape to print parts. Continuous fiber tape is applied along critical load paths in a process called Micro Automated Fiber Placement (µAFP). The technical innovation for this printer is led by Dr. Konstantine Fetfatsidis, Vice President of Composite Products for Desktop Metal, who was previously the advanced manufacturing R&D lead for Aurora Flight Sciences, a Boeing company.

What do you mean by critical load paths?

In continuous fibers all the fibers are aligned in the direction of the composite (impregnated) tape. The direction of the fibers cause the composite tape to have mechanical properties that are directional as well (anisotropic). The accurate control of the diection of the continuous fiber allows the user to impart customized mechanical properties to the 3D printed part. In the Desktop Metal Fiber™, this is done in a process called Micro Automated Fiber Placement.

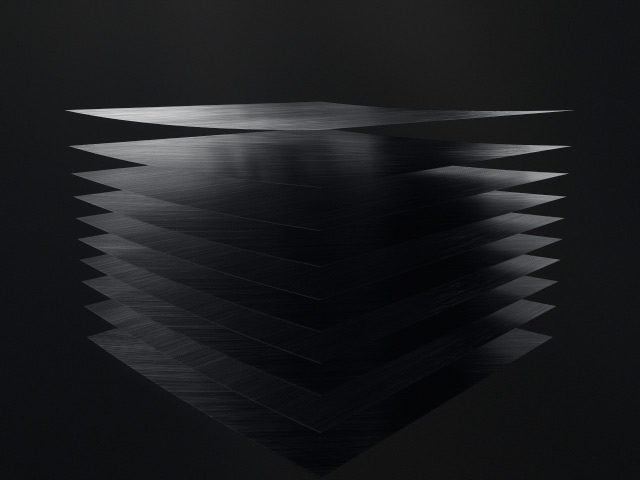

What is continous fiber tape?

The Desktop Metal Fiber™ printer allows users to make thermoplastic composite parts using continuous fiber (glass or carbon) in tape form. Continuous Fiber thermoplastics glass or carbon tapes are long strands of either glass or carbon fibers that have been impregnated (or prepreged) with a thermoplastic. The impregnation process allows the individual strands to be formed into a tape. Desktop Metal has continuous fiber tapes of carbon impregnated PA6 (Nylon), PEEK and PEKK. They also have continous fiber tape of glass impregnated with PA6 (Nylon).

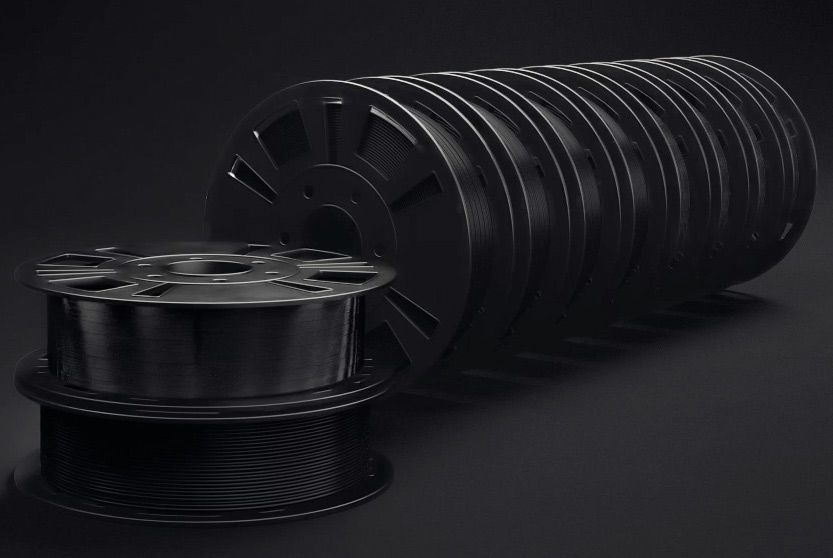

What are thermoplastic chopped fibers?

The Desktop Metal Fiber™ printer also uses chopped fiber thermoplastics. This thermoplastic comes in filament form. Desktop Fiber™ offers filaments of PA6 (Nylon), PEEK and PEKK with chopped carbon fibers and PA6 (Nylon) with chopped glass fiber. The difference between the chopped fiber and the continuous fiber is that in the chopped fiber filaments the fibers are chopped and are multidirectional.

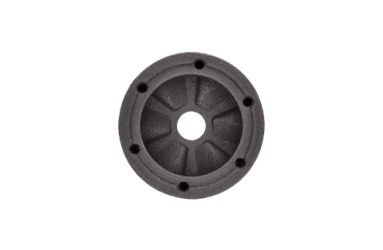

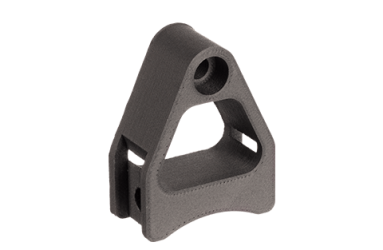

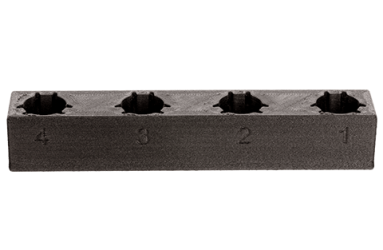

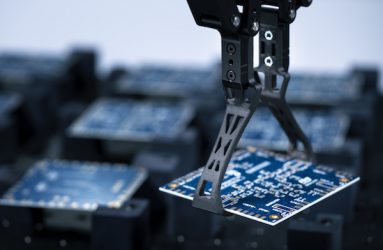

What kind of parts can I make?

Parts can be 3D printed that span a variety of industries including manufacturing, tooling, automotive, consumer, electronics, marine and more. If you own a small machine shop you can start to provide high performance customized parts such as CNC fixtures (see below). If you already sell automotive parts you can expand your offering to include customized parts such as exhaust heat shields (see above). If you have a hardware store you can compete with Home Depot by offering customized tools such as mirror and camera mounts (see below). If you are an engineer at a manufacturing plant you can produce parts such as end-of-arm tooling, including those used in electronics manufacturing (see below).

The Desktop Metal Fiber™ printer come in two flavors: Fiber™ LT & Fiber™ HT

- Micro Automated Fiber Placement (μAFP) and Fused filament fabrication (FFF) print technology.

- Standard configuration: 1 FFF head + 1 μAFP head

- Build Space: 310 x 240 x 270 mm (FFF only)

- Build Space: 290 x 210 x 270 mm (μAFP-reinforced)

- Layer height of 50-200 μm

- Maximum build rate of 20 cm3/hr

- Maximum Build Weight: 10kg

- Printhead Nozzle Diameter: 0.40 mm

- FFF build media: Thermoplastic filament / Chopped fiber 1.75 mm diameter

- μAFP build media: Thermoplastic μAFP prepreg tape / Continuous fiber 3 mm wide

- Reinforcement: Automated optimization

- Compatible materials: PA6 + CF, PA6 + FG

- Starter Material Included

- Ability to upgrade your printer at anytime to a higher or newer model

- Box for drying filament prior to printing to maximize success.

- State-of-the-art, cloud-based software for print preparation which includes cloud-based new releases and software updates.

- Desktop Metal has online resources that will provide you with guides for installation, operation, and troubleshooting.

- If you are uncertain about your Fiber™ Printer or Fabricate™ Software performance, or you have any questions or concerns, the Desktop support team is here to help you over the phone, email, or chat.

- Micro Automated Fiber Placement (μAFP) and Fused filament fabrication (FFF) print technology.

- Standard configuration: 2 FFF head + 1 μAFP head

- Build Space: 310 x 240 x 270 mm (FFF only)

- Build Space: 290 x 210 x 270 mm (μAFP-reinforced)

- Layer height of 50-200 μm

- Maximum build rate of 20 cm3/hr

- Maximum Build Weight: 10kg

- Printhead Nozzle Diameter: 0.40 mm

- FFF build media: Thermoplastic filament / Chopped fiber 1.75 mm diameter

- μAFP build media: Thermoplastic μAFP prepreg tape / Continuous fiber 3 mm wide

- Reinforcement: Automated optimization, Custom targeted reinforcement

- Compatible materials: PEEK + CF, PEKK + CF, PA6 + CF, PA6 + FG

- Starter Material Included

- Ability to upgrade your printer at anytime to a newer technology model

- Box for drying filament prior to printing to maximize success.

- State-of-the-art, cloud-based software for print preparation which includes cloud-based new releases and software updates.

- Desktop Metal has online resources that will provide you with guides for installation, operation, and troubleshooting.

- If you are uncertain about your Fiber™ Printer or Fabricate™ Software performance, or you have any questions or concerns, the Desktop support team is here to help you over the phone, email, or chat.

- PA6 Chopped Fiberglass

- PA6 Chopped Carbon Fiber

- PEEK Chopped Carbon Fiber

- PEKK Chopped Carbon Fiber

- PA6 Continuous Fiberglass

- PA6 Continuous Carbon Fiber

- PEEK Continuous Carbon Fiber

- PEKK Continuous Carbon Fiber

How can I purchase this machine?

Desktop Fiber™ is available in the Caribbean through Rich Port 3D Solutions. To learn how you can start 3D printing strong light parts for your customers or stakeholders contact Rich Port 3D Solutions your local Authorized Desktop Metal Reseller so that we may help you make an informed decision.

For a free consultation call today!