ROBOZE METAL REPLACEMENT PRINTERS WITH MECHANICAL ACCURACY

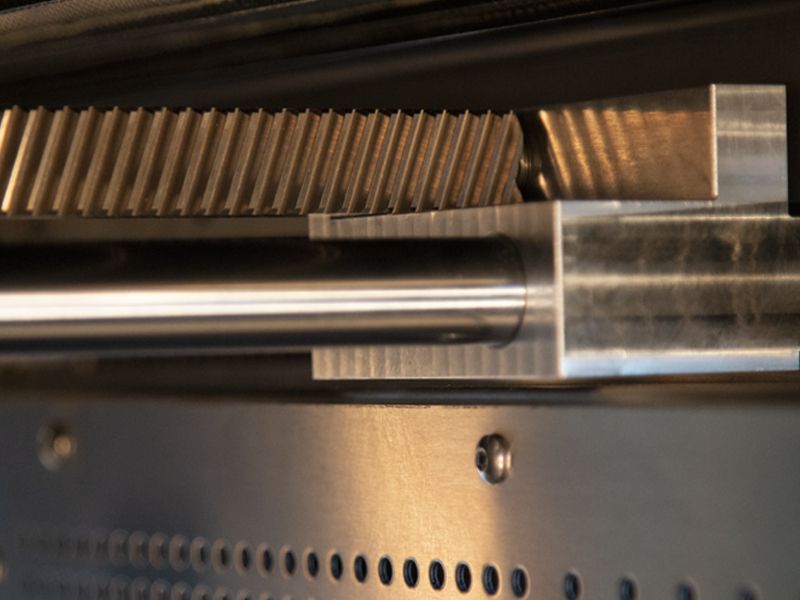

PATENTED BELTLESS SYSTEM brings MECHANICAL PRECISION to FFF 3D Printing Technology

Roboze has changed the rules of the game, bringing mechanical precision to the FFF 3D printing technology.

By eliminating the belts, and introducing a direct mechatronic movement of the X and Y axes entrusted to hardened steel rack and pinion, Roboze finally introduced real work precision.

In the Beltless system from Roboze, the positioning accuracy and repeatability of the movements is ensured by the gear teeth, in our case the helical gear also ensures smoothness of movement, quietness and positioning precision equal to 0.4 mil (0.01 mm).

All other FFF printers use rubber belts that are subject to deformation, irrepeatability of movement, wear and tear, and the need for continuous calibrations.

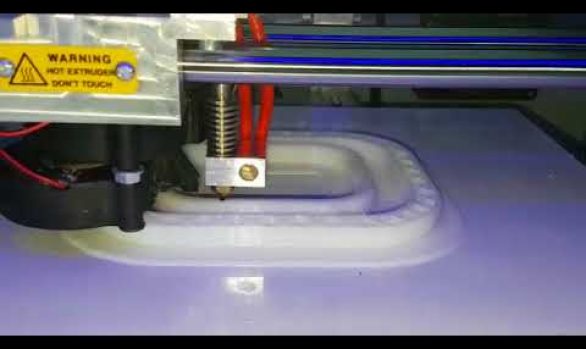

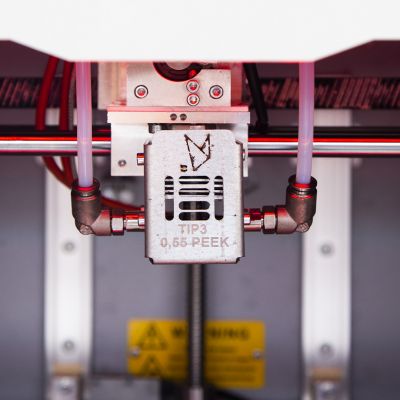

PATENT PENDING HVP EXTRUDER enables UNBEATABLE PRINT QUALITY

Designed and manufactured by Roboze, the High Viscosity Polymers (HPV) extruder represents an engineering jewel from Roboze R&D department using the capabilities of the CNC machines present in the Roboze plant.

The HVP Roboze extruder has a narrowing in the internal extrusion channel which allows acceleration of the speed of high viscosity polymers during the extrusion process. Moreover, together with the achievement of the optimal temperature, HVP reduces the ploymer's viscosity and controls the swelling phenomenon, increasing the printing speed of such polymers as PEEK.

The result is an absolutely unbeatable print quality in the engineering of plastic materials such as PEEK, with impressive precisions and incredible mechanical properties.

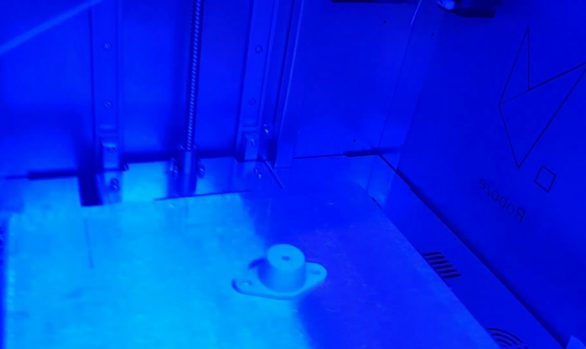

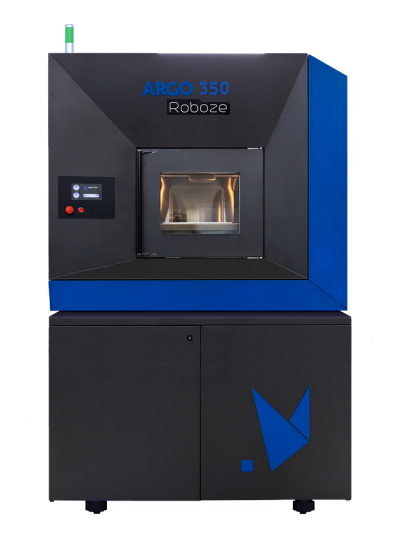

HEATED CHAMBER REMOVES THERMAL STRESSES of LARGE PRINTED PARTS

In order to minimize shrinkage phenomena of techno polymers in the extrusion phase and avoid any thermal stresses of the printed part (especially large prints) the Production systems by Roboze are equipped a printing chamber that has controlled heating environment. This chamber is capable of reaching 356°F (180 °C). In comparison with the other systems, the innovative ROBOZE chamber gets hot in a little over an hour, drastically reducing the time necessary to prepare the printing procedure.

Roboze heated chamber is designed to guarantee uniformity throughout its volume. The possibility of managing the temperature during the printing phase results in unique and unbeatable output quality.

HEAT TREATMENT PROCESS includes a FILIMAMENT DRYER that LOADS DRY FILAMENT AUTOMATICALLY

Heat Treatment Process is the system developed by Roboze engineers for the management of the entire production process of high temperature and composite materials. With the aim of increasing the quality of the printed parts and the productivity of the final user, the process includes the use of the Filament Dryer and the HT Oven.

The Filament Dryer is capable of loading the filament automatically and it is designed to dry the materials before and during the printing phase.

In order to meet the needs of thermal post-processing for the crystallization of the printed parts, ROBOZE HT Oven has been developed and produced to improve the mechanical performances at high temperatures, reducing residual stress. Moreover the preparation of the filaments while printing the next job, optimizing and speeding up production thanks to the large storage area for many spools of the same or different materials.

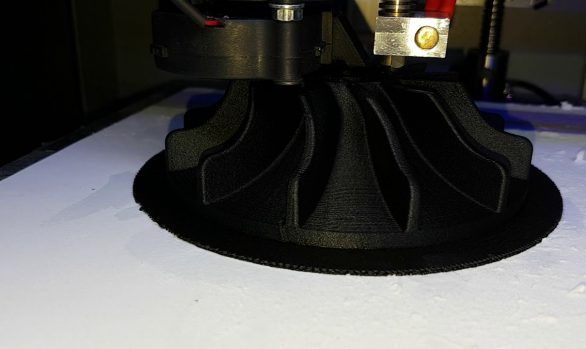

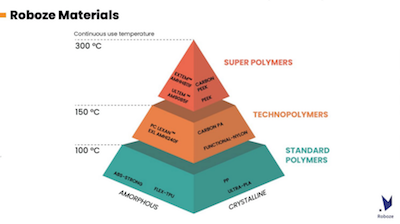

ROBOZE TECHNOLPOLYMERS are able to REPLACE METAL ALLOYS even under EXTREME APPLICATIONS

Roboze technologies offer cutting-edge 3D printing materials to meet the needs of sectors ranging from Aerospace to Automotive.

Roboze technolpolymers, with high thermal and mechanical resistance like Carbon PEEK and polymers with very high mechanical properties such as Carbon PA, are able to replace metal alloys even under extreme applications.

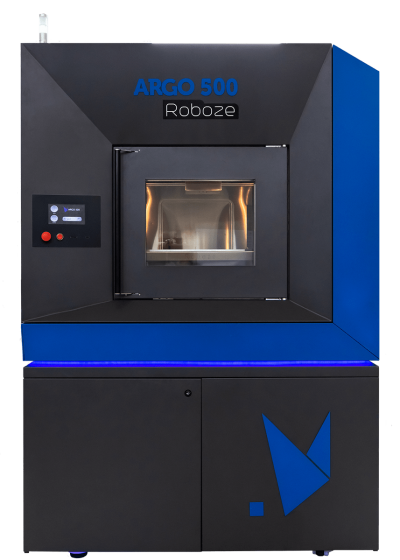

Choose a Printer to Learn More